Tesla expect another ‘Significant’ Toyota deal by 2017

During a recent trip to Japan, Tesla CEO Elon Musk says his company and Toyota could team on another “significant” joint project in two or three years, and at higher volumes than the soon-to-end RAV4 program.

Musk’s comments came just four months after Tesla Motors Inc. announced that the agreement to supply battery packs for the electric Toyota crossover would finish this year with sales around 2,500.

Musk said there were no concrete plans for a new vehicle with Toyota but dangled the possibility of a bigger project soon.

“I think that if you look out maybe two or three years from now, that I would not be surprised if there is a significant deal with Toyota,” Musk said today at a ceremony to deliver the first Tesla Model S sedans to customers in Japan.

“My best guess is that it would probably be something significant, maybe on a much higher volume level,” he said.

Toyota Motor Corp., which owns 2.4 percent of Tesla, said in May 2012 it envisioned building around 2,500 RAV4 EVs over three years. When the partners announced in May that the program would wrap this year, they were noncommittal about future projects.

The Japanese and American companies have since sparred over alternative visions for tomorrow’s alternative drivetrains.

Toyota has channeled its focus into hydrogen fuel cells, while dismissing EVs as impractical and impossibly short-ranged. Meanwhile, Tesla has beat the drum for batteries, while deriding cars powered by hydrogen stacks as “fool cells.”

Toyota spokesman Dion Corbett said the world’s biggest carmaker had “nothing to say” in response to Musk’s latest overture.

Toyota sold 2,130 RAV4 EVs through August. The company expects to sell the rest of the planned 2,500 by year’s end.

After those are delivered, Toyota will have neither a single EV nameplate in its lineup nor public plans to add one.

Musk was not expected to meet with Toyota officials during his visit to Japan. While in Tokyo, he handed over the keys to nine new Model S sedans on the 52nd-floor observatory of Roppongi Hills Mori Tower, one of the tallest buildings in town.

“We love working with Toyota,” he said. “We have a huge amount of respect for them as a company and certainly much to learn.”

Tesla Model S Vs Sunswift eVe.. 500 km range on 1/5 the battery capacity

Recently EV News had the opportunity to test drive two electric vehicles with 500 km range within a fortnight of each other. One, a world record breaking electric car, the University of New South Wales Sunswift eVe solar race car and the other a Tesla Model S P85+.

I wrote last year how in many ways the two share a common heritage with technology in the Tesla having a direct evolutionary path from the inaugural World Solar Challenge in 1987. While I was massively impressed by my short drive in the top-of-the-line Model S, it's interesting to analyse the strengths and weaknesses of two EVs that both achieve the holy grail of plug-in vehicles, 500 km range on a single charge.

Following Sunswift eVe's World Record run in July, Wired magazine hailed the student-run university project as being Tesla's new competitor, ahead of the likes of BMW or General Motors. Hyperbole? Perhaps as eVe is not a road registered vehicle let alone production ready. But that doesn't detract from the fact that during the world record run, Sunswift eVe achieved 500 km range at highway speeds of 107 km/h (66 mph), without solar array assistance, using a battery pack made of the exact same Panasonic cells used by Tesla but with 1/5 th the capacity of the Model S.

When you take into consideration that much of the Model S design, from the large wheelbase to the all Aluminium body construction, is dictated by the 500 km range goal and the size and weight of the battery pack required to achieve that, any vehicle that achieves energy efficiency sufficient to reduce the 18650 battery cell count from 7,104 to 1,200 must offer some advantages.

Number one on the list is direct drive in-wheel motors. Sunswift eVe is RWD and powered by 2x 1.8 Kw (10 Kw Peak) Australian developed direct drive CSIRO wheel motors, that give eVe a top speed of 140 km/h. These axial flux BLDC wheel motors are 98.3% energy efficient and because they are inside the wheel with the rotor turning at the same RPM as the tire, there is no mechanical transmission gearing losses which typically range from 20-30%.

Sure, rated power of only 1.8 kw is barely enough to run a 4 slice toaster but the driving experience proved that 20 kw peak (27 horsepower) provides enough performance to accelerate and maintain highway speeds with minimal fuss. Each wheel motor weighs in at only 15 kg with the 99.2% efficient motor inverters adding less than 1 kg each to over-all powertrain weight.

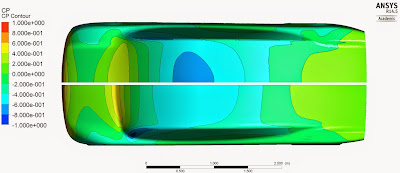

Next up is aero efficiency. Because the car was deigned for a 3,000 km race with a high average speed on extremely limited solar power, aerodynamic efficiency is king. Sunswift eVe has a 1800 x 4500 mm footprint (larger than a Tesla Roadster). Although the car has twice the frontal area of its blade-like solar car predecessor, Sunswift has achieved a similar drag coefficient. It’s managed this partly through a unique high-set “tunnel” underside design, giving the car the look of a catamaran.

Where the Tesla Model S has the lowest drag coefficient of any production vehicle of 0.24, Sunswift eVe, designed exclusively using Computational fluid dynamics (CFD), achieves a Cd of 0.16. During my test drive of eVe, even though the vehicle had both doors removed for easy access, the lack of aero drag was noticeable while coasting. One team member told me it takes eVe several kilometers to coast to a stop from 100 km/h.

While Tesla claimed that every panel on the Roadster was carbon fibre, UNSW has taken that a step further and fabricated the entire chassis from the material. Manufactured through a sponsorship deal with New Zealand firm Core Builders Composites, the company that build much of the America's Cup fleet, the vehicle has a kurb weigh of just 320 kg. A Tesla Model S weighs 2100 kg.

The main benefit of light weight is reduced rolling resistance. Approximately 5–15% of the fuel consumed by a typical car may be used to overcome rolling resistance. Michelin special order low rolling resistance tyres are used which are run at 80 psi. While not exactly the same kind of road car tires as the 285/30 R21 used on the rear of a P85+, they are possibly not too far removed from the bicycle like 155/70 R19 tires fitted to the BMW i3.The combination of electrical energy efficiency, low aero drag and rolling resistance means a 16 kWh battery made from 1200x Panasonic NCR18650 cylindrical Lithium Ion cells with a weight of only 63 Kg is enough to give eVe a single charge highway speed cruising range of over 500 km. That's the same battery capacity as a Mitsubishi iMiEV which has a maximum range of 155 km.

Although carbon fiber is roughly 20 times more expensive than steel, BMW have invested €400 million to launch the first carbon fibre reinforced plastic (CFRP) production car, the all electric i3. BMW’s goal is to get the expense of a carbon-fiber frame down to the level of aluminium by 2020. While only the passenger cabin of the i3 is made from carbon fiber with the drive train, battery and suspension attached to an aluminium chassis, it seems only a mater of time before 100% CF chassis like eVe become economically viable for mass produced road cars.

The next challenge for the Sunswift team is to make the eVe the first road-legal solar-powered car in Australia. They expect it to meet Australian road registration requirements within as little as one year.

Tesla to Roll Out “Destination Charging” Program At Hotels, Restaurants And Resorts

Tesla has begun installing high-power wall chargers at restaurants, hotels, beach parking and other locations that can send 80 amps of electricity into the Model S and add 58 miles of range in an hour. While that’s not nearly as fast as a Supercharger, which can recharge the 85 kWh pack in around 30 minutes, it’s twice as fast as the standard 240-volt chargers that can be more commonly be found around in parking lots and garages.

Tesla has been rolling these out quickly across the US as a convenience to customers. The company says 106 of them have been installed since the program began this spring, with more coming online daily. Like the Superchargers, they are free to use for Tesla owners.

Unlike Superchargers, which function more like a petrol station, these wall chargers are designed for destinations. Teslas can also use standard charging stations with the use of an adapter that comes with the car but due to the out-sized capacity of the battery in a Model S (up to 85 kWh), a full charge from a standard 240v 10 amp outlet might take as long as 30 hours. To make utilizing the full range of a Model S practical, for example for weekend trips, higher powered 'destination' charging is required to provide up to 500 km worth of charge in approx 4-5 hours.

A ‘quick’ test drive in a Tesla Model S P85+

Earlier this week EV News had the pleasure of test driving a Tesla Model S P85+ around the streets of Sydney. It was only a very brief experience compared to the week long test drives we've had with most other EVs, but it was long enough to confirm Tesla Motors electric vehicles are in another league.

The first thing you notice about the Model S is that it's a big car. All dimensions including wheelbase and track are larger than a Holden Commodore VF. The upshot of this being the Model S has more interior storage space (1,796 L) than the Mitsubishi Outlander PHEV SUV we tested a few weeks ago. The overall size of the wheelbase seems governed by the size of the flat-pack battery enclosure which makes up 700 kg of the vehicles 2,100 kg kerb weight.

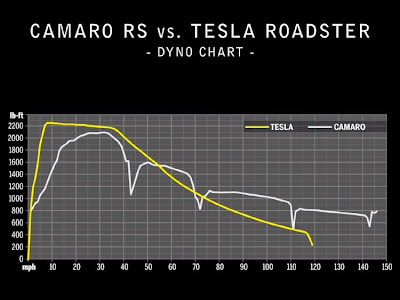

For such a heavy car the weight wasn't noticeable while driving, although the test route didn't allow for any high speed loaded cornering. In acceleration the P85 Model S is stunning! Unlike all other EVs I've driven which have synchronous BLDC permanent magnet motors, the asynchronous AC induction motor in the Model S really has a kick in the back off the line. So much so it might be a good idea for Tesla reps to wear a neck brace on test drives.

The BMW i3 I drove in Munich earlier this year was the fastest EV I had previously driven but full acceleration in the i3 didn't really come on strong until over approx 25 km/h. With 310 kw and 600 Nm peak torque from zero RPM from the 3 phase AC induction motor, the P85 Model S launches from a standing start to 100 km/h in just 4 seconds. That's faster than your average Porsche.

As with all EVs, mid-speed acceleration was impressive but with the Tesla, mind blowingly so! The main reason I've been so keen to sample a Model S was because my daily driver has 255 Kw / 500 Nm with a 1600 kg chassis, so on paper the two are broadly comparable. My 5.7 Lt 4 door sedan does 0-100 km/h in around 5 sec which is faster than both a standard Model S 85 (5.6s) the 60 version (6.2s). I've clocked up over 300,000 km in my current car so am fairly familiar with impressive acceleration, yet the Model S P85 absolutely kills it!

I've been trying to get my head around how the Tesla Model S P85's mid-speed acceleration felt twice as fast as my car. The Tesla's 600 Nm multiplied by the 9.73:1 reduction gear ratio gives 5,898 Nm at the rear wheels. Divide that by the 2,100 kg kerb weigh and the Model S has 2.8 Nm /kg. Running the same numbers for my Corvette engined family sedan gives 4,476 Nm (in first gear only) divided by 1,600 kg kerb weigh surprisingly gives the same 2.8 Nm/kg figure.

So why does the P85 feel twice as fast at mid speed? The 3 phase AC copper rotor induction motor's torque curve gives a flat 600 Nm between 0 and 5,000 rpm. Like with all EVs this broad torque curve allows the Tesla to have a single speed transmission. This means it's effectively in first gear all the time. So while my ICE powered car, even in 1st gear, doesn't reach peak torque until 4,400 rpm (although it has approx 80% of that from 1,500 rpm), cruising in top gear reduces maximum rear wheel torque to 'only' 1,500 Nm at mid-speeds. By comparison, the Tesla has approx 6,000 Nm available from standstill up to approx 70 km/h.

The bottom line is, at mid-speeds, the Tesla has up to 4x as much peak torque available at the flick of the throttle pedal compared to my ICE car and I can confirm, you can certainly feel the difference. The rep spotted the "Tesla grin" immediately. It's no surprise that Mercedes, Audi and BMW are already working on their own versions of the Model S. I don't think it's much of an exaggeration to say this car is revolutionary!

The Model S P85+ as driven was priced around $190k. A basic P85 option package with the full 310 kw / 600 Nm and 21" wheels is $130,600. Unfortunately luxury tax and other government charges add another $25k bringing the total cost to $155k in Australia.

Tesla Model S Drive Unit now has Infinite Mile Warranty

Following recent negative reports about Tesla Model S drive unit reliability, Tesla has increased the Model S drive unit warranty to match that of the battery pack. That means the 85 kWh Model S, the most popular model by far, now has an 8 year, infinite mile warranty on both the battery pack and drive unit. There is also no limit on the number of owners during the warranty period. Moreover, the warranty extension will apply retroactively to all Model S vehicles ever produced.

The drive unit is now covered under the same provisions as the existing battery warranty, so owners with an 85 kWh battery will benefit from eight years of coverage with no mileage restrictions, while 60 kWh owners have up to 125,000 miles.

The drive unit issue, described as a grinding or “milling” noise that increases over time, was picked up by Motor Trend Magazine who reported that they had to have a drive unit replaced in their Model S. The issue really hit the headlines when Edmunds reported they are on their 4th drive train.

Tesla had transmission issues with the Roadster. The two-speed transmission designed for the Roadster by a previous supplier proved not to be durable so in 2008 Tesla Motors selected BorgWarner for the production of a single-speed gearbox.

The source of the current 9.73:1 Model S gearbox is not known. Anecdotal evidence suggests the Borg Warner eGearDrives supplied for the the Ford eTransit Connect has quite a high failure rate but as the Model S transmission casting is integrated with the AC Induction motor enclosure and without knowing which component has suffered premature wear, it's too early to attribute blame for the design fault.

When you take into consideration how common transmission failures are within the automotive industry and how high performance the Tesla Model S is, it's not so surprising to find the powertrain needs some mechanical debugging. For example, Subaru have been making the Impresa WRX since 1992 and after two decades in production they're still prone to transmission failure. The only sure way to avoid mechanical transmission issues is to not have one by using direct drive wheel motors.

The standard warranty for Tesla Model S is 4 year, 50,000 mile (80,000 km). In April last year Tesla announced an unlimited "no-fault" battery warranty. Elon Musk says that in hindsight, the infinite warranty should have been policy for the powertrain from the beginning of the Model S program. If they truly believe that electric motors are fundamentally more reliable than gasoline engines, with far fewer moving parts and no oily residue or combustion byproducts to gum up the works, then the warranty policy should reflect that.

Fully Charged – Tesla Model S Road Trips [VIDEO]

Consumer Reports: Tesla Model S: Problems After 15,000 Miles

Silicon Carbide Power Electronics Can Slash $6,000 From Cost of Tesla Model S

Wide bandgap (WBG) materials such as silicon carbide (SiC) and gallium nitride (GaN) are best positioned to address emerging power electronics performance needs in electric vehicles (EVs), with SiC displacing silicon as early as 2020, according to Lux Research.

As silicon struggles to meet higher performance standards, WBG materials are benefiting critically from evolving battery economics. On Tesla Model S, for example, a 20% power savings can result in gains of over $6,000 in battery cost, or 8% of the vehicle's cost.

"Efficient power electronics is key to a smaller battery size, which in turn has a positive cascading impact on wiring, thermal management, packaging, and weight of electric vehicles," said Pallavi Madakasira, Lux Research Analyst and the lead author of the report titled, "Silicon vs. WBG: Demystifying Prospects of GaN and SiC in the Electrified Vehicle Market."

"In addition to power electronic modules, opportunities from a growing number of consumer applications -- such as infotainment and screens -- will double the number of power electronic components built into a vehicle," she added.

Lux Research analysts evaluated system-level benefits WBG materials are bringing to the automotive industry, and predicted a timeline for commercial roll-outs of WBG-based power electronics. Among their findings:

New Tesla Roadster coming in 2017

According to a recent report, Tesla could launch up to four new models by 2018.

While we already know about the Model X and the Model 3, Autobild is reporting the company is considering a compact city car.

Little is known about the vehicle - which has been dubbed the Model C - but it would be smaller and more affordable than the Model 3 which is expected to cost approximately $35,000.

The magazine goes says a new roadster - dubbed Model R - could arrive in 2017. This seems to contradict statements from Tesla CEO Elon Musk who has previously said an all-new Roadster is at least five years off. However, the wait could be worth it as Tesla's vice president of sales, George Blankenship, has previously suggested it could accelerate from 0-60 mph in less than four seconds and have a range in excess of 200 miles (322 km).

.jpg)

.jpg)