Created for the 2014 World Energy Innovation Forum, this short video showcases all things Tesla in just under two minutes.

Flexible supercapacitor demonstrates ultrahigh energy-density

Scientists have taken a large step toward making a supercapacitor with energy density comparable to a Li-ion battery.

The supercapacitor packs an interconnected network of graphene and carbon nanotubes so tightly that it stores energy comparable to some thin-film lithium batteries—an area where batteries have traditionally held a large advantage.

The product's developers, engineers and scientists at Nanyang Technological University (NTU) in Singapore, Tsinghua University in China, and Case Western Reserve University in the United States, believe the storage capacity by volume (called volumetric energy density) is the highest reported for carbon-based microscale supercapacitors to date: 6.3 microwatt hours per cubic millimeter.

The device also maintains the advantage of charging and releasing energy much faster than a battery. The fiber-structured hybrid materials offer huge accessible surface areas and are highly conductive.

The researchers have developed a way to continuously produce the flexible fiber, enabling them to scale up production for a variety of uses. To date, they've made 50-meter long fibers, and see no limits on length.

They envision the fiber supercapacitor could be woven into clothing to power medical devices for people at home, or communications devices for soldiers in the field. Or, they say, the fiber could be a space-saving power source and serve as "energy-carrying wires" in medical implants.

Liming Dai, a professor of macromolecular science and engineering at Case Western Reserve and a co-author of the paper, explained that most supercapacitors have high power density but low energy density, which means they can charge quickly and give a boost of power, but don't last long. Conversely, batteries have high energy density and low power density, which means they can last a long time, but don't deliver a large amount of energy quickly.

Microelectronics to electric vehicles can benefit from energy storage devices that offer high power and high energy density. That's why researchers are working to develop a device that offers both.

To continue to miniaturize electronics, industry needs tiny energy storage devices with large volumetric energy densities.

By mass, supercapacitors might have comparable energy storage, or energy density, to batteries. But because they require large amounts of accessible surface area to store energy, they have always lagged badly in energy density by volume.

Their approach

To improve the energy density by volume, the researchers designed a hybrid fiber.

A solution containing acid-oxidized single-wall nanotubes, graphene oxide and ethylenediamine, which promotes synthesis and dopes graphene with nitrogen, is pumped through a flexible narrow reinforced tube called a capillary column and heated in an oven for six hours.

Sheets of graphene, one to a few atoms thick, and aligned, single-walled carbon nanotubes self-assemble into an interconnected prorous network that run the length of the fiber. The arrangement provides huge amounts of accessible surface area—396 square meters per gram of hybrid fiber—for the transport and storage of charges.

But the materials are tightly packed in the capillary column and remain so as they're pumped out, resulting in the high volumetric energy density. The process using multiple capillary columns will enable the engineers to make fibers continuously and maintain consistent quality, Chen said.

The findings

The researchers have made fibers as long as 50 meters and found they remain flexible with high capacity of 300 Farad per cubic centimeter. In testing, they found that three pairs of fibers arranged in series tripled the voltage while keeping the charging/discharging time the same.

Three pairs of fibers in parallel tripled the output current and tripled the charging/discharging time, compared to a single fiber operated at the same current density. When they integrate multiple pairs of fibers between two electrodes, the ability to store electricity, called capacitance, increased linearly according to the number of fibers used.

Using a polyvinyl alcohol /phosphoric acid gel as an electrolyte, a solid-state micro-supercapacitor made from a pair of fibers offered a volumetric density of 6.3 microwatt hours per cubic millimeter, which is comparable to that of a 4-volt-500-microampere-hour thin film lithium battery.

The fiber supercapacitor demonstrated ultrahigh energy-density value, while maintaining the high power density and cycle stability. "We have tested the fiber device for 10,000 charge/discharge cycles, and the device retains about 93 percent of its original performance," Yu said, " while conventional rechargeable batteries have a lifetime of less than 1000 cycles."

The team also tested the device for flexible energy storage. The device was subjected to constant mechanical stress and its performance was evaluated. "The fiber supercapacitor continues to work without performance loss, even after bending hundreds of times," Yu said. "Because they remain flexible and structurally consistent over their length, the fibers can also be woven into a crossing pattern into clothing for wearable devices in smart textiles." Chen said.

Such clothing could power biomedical monitoring devices a patient wears at home, providing information to a doctor at a hospital, Dai said. Woven into uniforms, the battery-like supercapacitors could power displays or transistors used for communication. The researchers are now expanding their efforts. They plan to scale up the technology for low-cost, mass production of the fibers aimed at commercializing high-performance micro-supercapacitors.

In addition, "The team is also interested in testing these fibers for multifunctional applications, including batteries, solar cells, biofuel cells, and sensors for flexible and wearable optoelectronic systems," Dai said. "Thus, we have opened up many possibilities and still have a lot to do."

Airbus Electric Airplane Flies—For an Hour Per Charge [VIDEO]

The Airbus E-Fan, an all-electric trainer aircraft made of composite material, made its first flight last month–proving once again that it is possible to fly without jet fuel.

That’s with one caveat however: The plane can fly for about an hour on a single charge. But still, this seems like a big deal mainly because the largest aerospace and defense company in Europe and the world’s leading commercial aircraft manufacturer is backing it.

The successful first public flight of the electric E-Fan experimental aircraft was the highlight of Airbus Group’s E-Aircraft Day in Bordeaux, France on April 25. The electric E-Fan training aircraft is an experimental demonstrator based on an all-composite construction. Airbus Group and its partners intend to perform research and development to construct a series version of the E-Fan and propose an industrial plan for a production facility close to Bordeaux Airport. In addition, the group’s research efforts support the environmental protection goals of the European Commission, as outlined in its Flightpath 2050 program.

Built with an all-composite construction, the E-Fan is 22 feet long and has a wingspan of 31 feet. It looks like a toy version of a jet aircraft with a pair of nacelles that aren’t really jets, but two ducted, variable pitch fans spun by two electric motors with a combined power of 60 kW. The ducting increases the thrust while reducing noise, and by centrally mounting them, the fans provide better control. The E-Fan flies at only 114 miles per hour.

Powering the fans are a series of 250-volt, lithium-ion polymer batteries made by Kokam of South Korea. These batteries are mounted in the inboard section of the wings and carry enough charge for up to one hour of flight. They can be recharged in one hour. Worried about the “recharge” light coming on while up in the air? There’s a backup battery for emergency landings.

Another key technology on the E-Fan is its e-FADEC energy management system, which automatically handles the electrical systems. According to Airbus, this simplifies system controls and, since E-Fan is a trainer, eases the workload of instructors and students.

The E-Fan has zero carbon dioxide emissions in flight and should bring a significant reduction in noise around airfields, according to Airbus, “thus improving relations between local residents and flight schools with long-term prospects for the discreet and economical initial training of future professional pilots.”

“It will not only lead to a further reduction in aircraft emissions and noise to support our environmental goals but will also lead to more economic and efficient aircraft technology in the long run. Our focus is to develop innovations that will help define what tomorrow’s aerospace industry will look like,” said Airbus Group Chief Technical Officer Jean Botti.

So today the E-Fan is a learning platform, tomorrow a larger hybrid version that can fly 80 passengers on short regional trips. That’s apparently the plan. From small beginnings, a revolution in the air.

Tasty Tech Eye Candy Of The Week (May 18)

Electric car tax credit should be $10,000 says Congressman

Vermont Rep. Peter Welch wants to make it easier to buy electric cars by increasing the size of the federal tax credit for the vehicles and making those credits available at car dealerships.

The Democrat said increasing the size of the tax credit to $10,000 and making it easier to take advantage of would make the vehicles more affordable for middle-income people.

Electric car buyers are now eligible for credits up to $7,500 through their tax return.

"If we're going to make real progress on climate change and we're going to reduce the cost of transportation, by the way, the cost of gas to our consumers, then we want to make this technology available," Welch said at an electric vehicle charging station near the Statehouse.

Welch said he planned to introduce the legislation for the Electric Vehicle Act when he returns to Washington.

More electric vehicles are needed because the transportation sector is the biggest contributor to greenhouse gases in Vermont, he said. Electric vehicles have become more practical because battery technology is improving, making it possible for people to drive longer distances without charging, Welch said.

Welch was joined at the Montpelier news conference by Montpelier Mayor John Hollar, Karen Glitman, the director of the Transportation Efficiency Program at the Vermont Energy Investment Corporation, and Dan Keene, owner of Lamoille Valley Ford and Twin State Ford.

Glitman said the number of electric vehicles sold in Vermont last year tripled and there are about 640 plug-in electric vehicles registered in Vermont. The number is still small, but it is increasing and the potential savings to Vermont consumers is huge, she said.

In 2010, there were $1.1 billion in taxable gasoline and diesel fuel sales in Vermont. If that amount of travel were provided by electric vehicles charged at the current cost of residential electricity, it would save about $800 million a year.

"We need to keep that money with Vermonters and keep it working in Vermont rather than sending it overseas for the most part," Glitman said.

NISMO ZEOD RC’s Electrical System Explained [VIDEO]

Jason from Engineering Explained has a look at the ZEOD RC's Electrical Systems and Zero Emissions on Demand motors that are capable of making the car go at 300km per hour!

While the video does show a close-up of the enclosure for the 400 volt 12 kWh battery, the only other details provided are that the twin BLDC motors are rated at 120 kw each.

GreenTech Scatters New Seeds

Airbus Charged Up About Electric Planes

Wheelies: The Top-Shelf Kia Edition

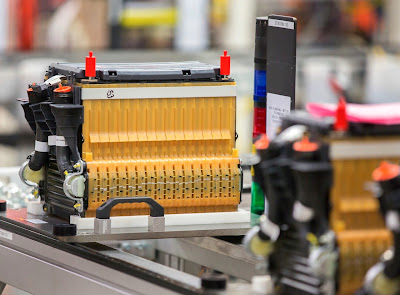

GM to Build Chevy Spark EV 19 kWh Batteries In House

General Motors will bring all its electric vehicle battery building capabilities in-house with production of battery systems for the 2015 Chevrolet Spark EV at its battery assembly plant in Brownstown, Mich.

"Using our in-house engineering and manufacturing expertise enabled us to deliver a battery system that is more efficient and lighter than the 2014 Spark EV without sacrificing range," said Larry Nitz, executive director of GM global transmission and electrification engineering. "Our successful working relationship with LG Chem has allowed us to deliver a new battery system for the Spark EV that helps us to better leverage our economies of scale."

A newly designed battery system features an overall storage capacity of 19 kWh and uses 192 lithium ion cells. The cells are produced at LG Chem's plant in Holland, Mich. The battery system weight of 474 lbs. is 86 pounds lighter than the system in the 2014 Spark EV. The Spark EV battery is built on a dedicated production line at Brownstown, which also manufactures complete battery packs for the Chevrolet Volt, Opel Ampera and Cadillac ELR.

Changes in battery design will not affect the Spark's MPGe, or gasoline equivalent, performance compared to the 2014 model. Range will remain at an EPA-rated 82 miles and MPGe will remain at 119.

Priced at $19,995 with full federal incentives, The Spark EV is one of the most efficient – and affordable – all-electric vehicles available. Currently on sale in California and Oregon, the 2015 Spark EV features segment-leading technology including Siri Eyes Free, 4G LTE and DC Fast Charging.

Brownstown Battery Assembly's 479,000-square-foot, landfill-free facility south of Detroit produces the lithium-ion battery packs for GM's extended-range electric vehicles. It started mass production in October 2010 and is the first high-volume manufacturing site in the U.S. operated by a major automaker for automotive lithium-ion battery production. The site was made possible with the help of American Recovery and Reinvestment Act funding through the U.S. Department of Energy.