Tesla Model S Vs Sunswift eVe.. 500 km range on 1/5 the battery capacity

Recently EV News had the opportunity to test drive two electric vehicles with 500 km range within a fortnight of each other. One, a world record breaking electric car, the University of New South Wales Sunswift eVe solar race car and the other a Tesla Model S P85+.

I wrote last year how in many ways the two share a common heritage with technology in the Tesla having a direct evolutionary path from the inaugural World Solar Challenge in 1987. While I was massively impressed by my short drive in the top-of-the-line Model S, it's interesting to analyse the strengths and weaknesses of two EVs that both achieve the holy grail of plug-in vehicles, 500 km range on a single charge.

Following Sunswift eVe's World Record run in July, Wired magazine hailed the student-run university project as being Tesla's new competitor, ahead of the likes of BMW or General Motors. Hyperbole? Perhaps as eVe is not a road registered vehicle let alone production ready. But that doesn't detract from the fact that during the world record run, Sunswift eVe achieved 500 km range at highway speeds of 107 km/h (66 mph), without solar array assistance, using a battery pack made of the exact same Panasonic cells used by Tesla but with 1/5 th the capacity of the Model S.

When you take into consideration that much of the Model S design, from the large wheelbase to the all Aluminium body construction, is dictated by the 500 km range goal and the size and weight of the battery pack required to achieve that, any vehicle that achieves energy efficiency sufficient to reduce the 18650 battery cell count from 7,104 to 1,200 must offer some advantages.

Number one on the list is direct drive in-wheel motors. Sunswift eVe is RWD and powered by 2x 1.8 Kw (10 Kw Peak) Australian developed direct drive CSIRO wheel motors, that give eVe a top speed of 140 km/h. These axial flux BLDC wheel motors are 98.3% energy efficient and because they are inside the wheel with the rotor turning at the same RPM as the tire, there is no mechanical transmission gearing losses which typically range from 20-30%.

Sure, rated power of only 1.8 kw is barely enough to run a 4 slice toaster but the driving experience proved that 20 kw peak (27 horsepower) provides enough performance to accelerate and maintain highway speeds with minimal fuss. Each wheel motor weighs in at only 15 kg with the 99.2% efficient motor inverters adding less than 1 kg each to over-all powertrain weight.

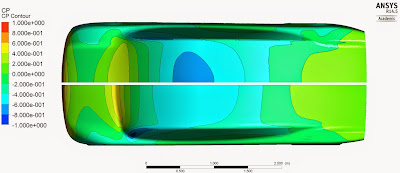

Next up is aero efficiency. Because the car was deigned for a 3,000 km race with a high average speed on extremely limited solar power, aerodynamic efficiency is king. Sunswift eVe has a 1800 x 4500 mm footprint (larger than a Tesla Roadster). Although the car has twice the frontal area of its blade-like solar car predecessor, Sunswift has achieved a similar drag coefficient. It’s managed this partly through a unique high-set “tunnel” underside design, giving the car the look of a catamaran.

Where the Tesla Model S has the lowest drag coefficient of any production vehicle of 0.24, Sunswift eVe, designed exclusively using Computational fluid dynamics (CFD), achieves a Cd of 0.16. During my test drive of eVe, even though the vehicle had both doors removed for easy access, the lack of aero drag was noticeable while coasting. One team member told me it takes eVe several kilometers to coast to a stop from 100 km/h.

While Tesla claimed that every panel on the Roadster was carbon fibre, UNSW has taken that a step further and fabricated the entire chassis from the material. Manufactured through a sponsorship deal with New Zealand firm Core Builders Composites, the company that build much of the America's Cup fleet, the vehicle has a kurb weigh of just 320 kg. A Tesla Model S weighs 2100 kg.

The main benefit of light weight is reduced rolling resistance. Approximately 5–15% of the fuel consumed by a typical car may be used to overcome rolling resistance. Michelin special order low rolling resistance tyres are used which are run at 80 psi. While not exactly the same kind of road car tires as the 285/30 R21 used on the rear of a P85+, they are possibly not too far removed from the bicycle like 155/70 R19 tires fitted to the BMW i3.The combination of electrical energy efficiency, low aero drag and rolling resistance means a 16 kWh battery made from 1200x Panasonic NCR18650 cylindrical Lithium Ion cells with a weight of only 63 Kg is enough to give eVe a single charge highway speed cruising range of over 500 km. That's the same battery capacity as a Mitsubishi iMiEV which has a maximum range of 155 km.

Although carbon fiber is roughly 20 times more expensive than steel, BMW have invested €400 million to launch the first carbon fibre reinforced plastic (CFRP) production car, the all electric i3. BMW’s goal is to get the expense of a carbon-fiber frame down to the level of aluminium by 2020. While only the passenger cabin of the i3 is made from carbon fiber with the drive train, battery and suspension attached to an aluminium chassis, it seems only a mater of time before 100% CF chassis like eVe become economically viable for mass produced road cars.

The next challenge for the Sunswift team is to make the eVe the first road-legal solar-powered car in Australia. They expect it to meet Australian road registration requirements within as little as one year.

A Green Rival for Formula One

Nevada a Winner in Tesla’s Battery Contest

Foxconn invest $800M to build electric cars in China

Foxconn Technology Group, the maker of Apple’s iPhone, is investing at least 5 billion yuan (US$811 million) to develop electric car manufacturing in a Chinese province.

The Taiwanese company is making the investment in China’s Shanxi province, it said on Wednesday. Foxconn already has two factories in the province. One of these assembles smartphones while the other is devoted to producing robots and automation equipment, it added.

Foxconn has largely focused on electronics manufacturing for clients including Microsoft, Sony and Amazon.com. But the company is branching out into new business sectors, as a way to grow its revenue streams. Analysts estimate that it makes as much as half of its revenue from assembling Apple products.

In June, Foxconn’s CEO Terry Gou said that the company is targeting to build electric cars with a price of less than $15,000.

Foxconn has already been developing electric car batteries for some time, and the company has many customers for them, he added. It also manufactures the touchscreen panels found inside the electric cars from Tesla Motors.

Foxconn Technology Group and BAIC Motor Corporation recently agreed to jointly establish a company that provides electric vehicle rental services, set to become operational in September. BAIC launched the E150 EV in China earlier this year.

The BAIC E150 EV is powered by an 60 hp and 144nm electric motor powered by a 25.6kwh lithium-ion battery. Top speed is 125km/h, range is 150km. Price range from $20.300 to 22.000.

China is mandating that electric cars make up at least 30 percent of government vehicle purchases by 2016, the latest measure to fight pollution and cut energy use after previously exempting EVs from a purchase tax.

Nevada and Tesla Hint at Site of Factory

Kia pushes energy-density frontier with Soul EV battery [VIDEO]

Kia Motors is using a 360-V lithium-ion battery pack of “class-leading” energy density (200 W·h/kg) in the 2015 Soul EV to give it range of about 200 km (125 mi) on the European Driving Cycle, and “real-world” range of 80-100 mi (129-161 km) in the U.S. The cells and the battery are the same in all regions.

The battery in the 2015 Kia Soul EV is the result of a three-year development program with lithium-ion cell maker SK Innovation. The 192 cells are packaged into eight modules and deliver a total battery capacity of 27 kW·h. The cell cathode is of nickel-rich NCM (nickel-cobalt-manganese) chemistry, with the raw materials for that and other components optimized for energy density, durability, and safety.

Kia says high-performance anode and gel electrolyte additive materials were developed. The new electrolyte additive allows for better range by more effectively dealing with low and high temperatures. A “special” ceramic separator with improved thermal resistance properties is used.

The cell casings are of polymer pouch type (as opposed to metal), and the battery pack is air-cooled. Standard equipment on the Soul EV includes receptacles for SAE J1772 Level 1 and Level 2 ac charging, as well as CHAdeMO dc fast charging (480 V).

The car goes on sale in the U.S. in third quarter 2014.

Tesla to Roll Out “Destination Charging” Program At Hotels, Restaurants And Resorts

Tesla has begun installing high-power wall chargers at restaurants, hotels, beach parking and other locations that can send 80 amps of electricity into the Model S and add 58 miles of range in an hour. While that’s not nearly as fast as a Supercharger, which can recharge the 85 kWh pack in around 30 minutes, it’s twice as fast as the standard 240-volt chargers that can be more commonly be found around in parking lots and garages.

Tesla has been rolling these out quickly across the US as a convenience to customers. The company says 106 of them have been installed since the program began this spring, with more coming online daily. Like the Superchargers, they are free to use for Tesla owners.

Unlike Superchargers, which function more like a petrol station, these wall chargers are designed for destinations. Teslas can also use standard charging stations with the use of an adapter that comes with the car but due to the out-sized capacity of the battery in a Model S (up to 85 kWh), a full charge from a standard 240v 10 amp outlet might take as long as 30 hours. To make utilizing the full range of a Model S practical, for example for weekend trips, higher powered 'destination' charging is required to provide up to 500 km worth of charge in approx 4-5 hours.

London’s hybrid buses to wirelessly recharge at stops

Hybrid London buses that use batteries and a motor will now start recharging at stops, wirelessly. The inductive charge should mean the engine won't need to be used as much, or at all.

The inductive charging, built into the bus stops, will be trialled by TfL in four stops in east London from next year. The special Enviro400H E400 hybrid buses, with wireless charging capabilities, will run on route 69 between Canning Town and Walthamstow.

By keeping the batteries topped up the buses should be able to run longer in battery mode meaning lower running costs and less environmental damage. The journey should offer less vibrations and noise while travelling too. The trial should help enhance the electric bus offerings in London.

There are currently six pure electric buses being tested in London also. The Mayor of London wants the city to be the world's first Ultra Low Emission Zone by 2020. There are currently 800 hybrid buses operating in London with 1,700 expected in 2016 – making up 20 per cent of the total bus fleet.

Mike Weston, TfL’s Director of Buses, said: "We are continuing our assessment of new technology in the capital that can deliver genuine environmental benefits. This trial of extended range diesel electric hybrid buses, utilising the latest inductive charging technology, could be a step closer to getting even cleaner double deck buses on London’s streets. We will be closely monitoring the results of the trials, which may help us adopt this new cleaner technology more widely in London."

Mitsubishi Outlander PHEV to enter 2014 Australian Safari

Mitsubishi’s top selling Outlander PHEV plug-in hybrid electric vehicle is set to tackle a new frontier when it takes on one of the toughest off-road events in outback Australia next month.

With technical support from Mitsubishi Motors Australia (MMAL), Team Mitsubishi Ralliart Australia (TMR Australia) will enter a plug-in hybrid Outlander PHEV in the iconic Australasian Safari, which takes place in Western Australia from 19-27 September.

It will be the first plug-in hybrid four-wheel drive officially entered in an Australian motorsport event – including the Safari, which is considered one of the most demanding off-road endurance rallies in Australia.

Experienced local driver and co-driver team of Steve Glenney and Bernie Webb will put the TMR Australia petrol electric Outlander PHEV through its paces during the nine-day outback event.

The Outlander PHEV will compete in class A1 for production vehicles, in a category specially created for hybrid or dual powered vehicles.

TMR Australia’s Australasian Safari entry marks the third international off-road rally outing for an Outlander PHEV since its launch in late 2012. Previously, the Outlander PHEV’s all-terrain performance and durability have been tested in the Thailand, Cambodia Asia Cross Country Rally, which the Mitsubishi SUV successfully completed in 2013 and 2014.

TMR Australia Outlander PHEV Safari Team Principal Alan Heaphy said the Australasian Safari is a challenging event that demands stamina and endurance from competitors and vehicles alike.

“We’re very excited about building the first plug-in hybrid to compete in the Australasian Safari,” he said.

“The Outlander PHEV showcases the latest Mitsubishi hybrid and four-wheel drive technology, making it an ideal platform for an entry in the Australasian Safari.

“From our long-term experience working with Mitsubishi products, the quality of engineering and technology is a good match for motorsport, and we’re looking forward to proving the Outlander PHEV’s durability and technology in genuine off-road conditions.”

Competing in Australasian Safari production class A1, the Outlander PHEV will be built to meet FIA specification with only minor modifications made for durability and safety.

To help it withstand the punishing conditions, the Outlander PHEV will have extra underbody and frontal protection, reinforced suspension arms and strut towers along with competition brake pads, rally tyres and springs with adjustable dampers for added strength and durability.

The Mitsubishi Outlander PHEV is the world’s first plug-in hybrid SUV. It uses Mitsubishi Motors’ advanced electric vehicle technology by combining a 2.0L MIVEC petrol engine with high output 60kW twin front and rear motors, high capacity 12kWh drive battery and regenerative braking system for maximum efficiency and performance.

Mitsubishi Motor Company will support the TMR Australia Outlander PHEV Safari entry by sending three plug-in hybrid specialist engineers to Western Australia for technical assistance during the gruelling seven day event, which will cover more than 2,500 competitive kilometres through sand, salt plains, dry river beds and rugged desert tracks.

The 2014 Australasian Safari concludes in Kalbarri – 600 kilometres north of Perth – on Saturday 27 September.