Renault announces EOLAB – an environmental prototype with nearly 100 technological innovations designed to deliver ultra-low fuel consumption, of one litre per one hundred kilometres, whilst maintaining established B-segment levels of performance, practicality and affordability.

Scheduled to have its World Premiere at the 2014 Paris Motor Show on 2 October EOLAB not only previews innovative technology that is destined to be introduced on production Renaults from now until 2020 but also the vision of such a realistic and affordable B-segment car that will appear within 10 years.

EOLAB, which takes its name from combining the name of ‘Aeolous’ God and Ruler of the Winds in Greek mythology, and ‘Laboratory’, is capable of achieving 1l/100km (282mpg) and 22g/km CO2 emissions on the official NEDC cycle.

To achieve such low figures, the designers focused their efforts on three main areas: minimising weight, refining aerodynamics and using “Z.E. Hybrid” technology for all, a brand new initiative which permits zero emissions* motoring during everyday use.

As an innovative showcase with an environmental core, EOLAB includes a very high number of technological advances that are destined to be carried over gradually to vehicles available in the showroom. As a consequence, EOLAB underlines the undertaking of Renault – already a pioneer in the field of zero-emission mobility** thanks to its range of electric vehicles** – to take even greater steps to produce affordable models that have an increasingly smaller carbon footprint.

Technologies geared to achieving ultra-low fuel consumption for all

For Renault, the purpose of EOLAB is to remain true to the company’s DNA by ensuring that ultra-low fuel consumption becomes a reality for as many people as possible. This in turn means making its technologies available at a price that people can afford. EOLAB features materials such as magnesium and aluminium, which are extremely light and also much cheaper than titanium. Meanwhile, the notion of such a car being produced in large numbers within the next 10 years was dialled into the plan from the very start.

100 technological advances for future Renaults

EOLAB is much more than just a styling exercise or a mere shop window. Conceived around a B-segment platform, the prototype incorporates around 100 new, realistic technological developments that are designed to be introduced gradually on upcoming Renault vehicles.

EOLAB’s recipe

The EOLAB prototype’s exceptional fuel economy – namely 1 litre/100km – is the fruit of work on three main fronts: refined aerodynamics, weight saving and Z.E. Hybrid technology (petrol/electricity):

The car’s shape was designed to slice through air efficiently, while movable devices such as an active spoiler and lateral vanes perform the same way as ailerons. A weight saving programme brought the car’s mass down 400kg, thanks in particular to a multi-material body shell combining steel, aluminium and composites, as well as a remarkable magnesium roof that tips the scales at barely 4kg. Saving weight was a virtuous circle since it enabled the size, and therefore the cost of the prototype’s chief assemblies (engine, battery, wheels, brakes, etc.) to be kept low, thereby financing the decision to employ certain more costly materials; Z.E. Hybrid technology: this new, compact and affordable hybrid power unit combines ultra-low fuel consumption with zero-emission mobility* for journeys of less than 60km and at speeds of up to 120kph. In coming years, Z.E. Hybrid technology will become complementary to Renault’s zero-emission* electric vehicle range. A contribution to the French government’s ‘New Industrial Plan’

EOLAB forms part of the ‘fuel consumption of 2 litres/100km for all’ plan introduced within the framework of France’s so-called New Industrial Plan. However, EOLAB goes further than the fuel consumption target set by the French government since it sets its sights on the much longer term. In the course of the prototype’s design, Renault developed the technologies necessary for the introduction of a car with fuel consumption of just 2 litres/100km by 2020. To achieve this, Renault worked in a spirit of collaborative innovation with French automotive industry partners like car glass manufacturer Saint-Gobain, seat supplier Faurecia, tyre company Michelin and Continental (brake system). Renault also worked closely with major partners like the Korean company Posco (magnesium components). The specific know-how of all these partners made a valuable contribution to the success of the EOLAB prototype.

EOLAB Concept: a concept car to capture the imagination

Renault’s designers were closely involved with the EOLAB project from its very early days. In the case of EOLAB Concept, they pushed the design parameters to perfect the car’s styling and paid significant attention to detail in order to optimise aerodynamics and weight. With its sloping roof and breathtakingly slender rear end, the concept car’s true purpose is well masked: beneath its seductively designed shell, everything is geared towards frugality. It demonstrates that Renault is able to add a touch of dream-like magic to a prototype whose fundamental mission is to achieve ultra-low fuel consumption.

EOLAB: Overview

Around 100 new, realistic technological developments designed to be introduced gradually on new production Renaults from now until 2020 Aerodynamics of 0.235 Cd (30 per cent less than equivalent Clio) Active ride height: Access mode, Urban mode and Extra-Urban mode Active wheels – react to brake temperature to maximise Cd Active front spoiler Active rear flaps Weight savings across the entire vehicle (400kg over equivalent Clio) Asymmetric 3-door layout Compact revised brakes – no master cylinder & all systems integrated into one small lightweight unit Narrow 145/45R17 Michelin ultra-low consumption tyres Ultra-thin windscreen glass (3mm) – saves 2.6kg Thinner interior trim & lighter plastics containing air bubbles Optimised seat structures – save 12kg and 30mm in car length Lightweight dashboard cross member Lighter running gear – steel to aluminium Magnesium roof weighs just 4.5kg Brakes are 14.5kg lighter but retain the same braking efficiency Fixed bonnet gains 2.5kg LED front lights Lithium –ion battery Compact centre-exit exhaust system to save weight 100% Renault Z.E. Hybrid powertrain 1.0-litre 3-cylinder 75hp SCe petrol engine 400V, 6.7 kWh battery with 66km range Innovative patented clutchless 3-gear transmission Human Machine Interface – connectivity and real-time eco-driving information RENAULT’S INNOVATIVE ENVIRONMENTAL SHOWCASE

Consistently a step ahead in the fight to reduce the automobile industry’s carbon footprint

1. EOLAB FITS PERFECTLY WITH RENAULTS ECO2 ENVIONMENTAL HALLMARK

EOLAB is an eloquent demonstration of Renault’s determination to take ever greater steps to reduce the carbon footprint of its vehicles. The goal is to make ultra-low fuel consumption an affordable reality to as many motorists as possible.

As a pioneer in the field of zero-emissions mobility thanks to its range of electric vehicles, and also as the 2013 market leader in terms of fuel consumption and average CO2 emissions, Renault is the only manufacturer to have set a target of reducing its carbon footprint by 10 per cent over three years (2010-2013). That goal was achieved in 2013 and the brand continues to be committed to reducing the CO2 emissions of its vehicles during road use, which accounts for about 85 percent of the company’s total carbon footprint. Thanks to its range of all-electric vehicles and increasingly efficient internal combustion engines, the Renault Group recorded the lowest CO2 emissions figures of all European manufacturers in 2013 (less than 115g/km)*.

* Average CO2 emissions over an NEDC-homologated combined cycle of Renault group passenger vehicles registered in 2013, taken across 23 countries (all of the EU except Cyprus, Malta, Romania and Bulgaria). Source data from AAA-DATA (Association Auxiliaire de l’Automobile), a CCFA subsidiary. AAA-DATA is an association that manages automotive industry data for public authorities. * No CO2 or other regulated polluting emissions during road use.

The introduction of EOLAB takes Renault’s environmental programme to an even higher level. The target? To make ultra-low fuel consumption as widely available as possible by creating a prototype which blends a raft of cutting-edge features that are realistic in both technical and financial terms.

EOLAB’s purpose is to highlight Renault’s savoir-faire in the fields of design and technology. It is a statement of the company’s environmental strategy which strives to reduce the carbon footprint of its vehicles across successive generations.

It packs about 100 technological features that will be introduced gradually to the model range over the next 10 to 15 years with a view to meeting the following targets:

1. Meet various legislative requirements in different markets and also the Group’s commitment to reduce its global carbon footprint (Renault is aiming for a 10 percent fall between 2013 and 2016).

2. Meet customers’ expectations by increasing energy economy and cutting running costs at a time of uncertainty about the availability and price of resources.

3. Improve air quality in towns and cities, in line with the wishes of public authorities and motorists.

Renault’s internal combustion engines have become significantly more fuel efficient over the past decade or so.

Technological breakthroughs in terms of construction materials and vehicle design (for lightness, aerodynamic efficiency, etc.) will enable further savings to be made in the future.

The increasing electrification of powertrains is symbolic of both improving fuel economy and an opportunity to reduce vehicles’ CO2 emissions. It will also gradually increase the influence of renewable energies and improve overall energy efficiency from well to wheel.

EOLAB’s powertrain benefits from expertise acquired during the development of the Group’s electric vehicle range which remains unmatched even today. The technology it packs is innovative in the sense that it enables users to cover substantial distances in built-up areas without any exhaust emissions, then if necessary switch over to a conventional internal combustion engine to continue the journey. As with all Renault projects, the chief challenge was to develop a solution that is affordable to as many people as possible, and thus liable to sell in high numbers. That’s a vital consideration if we are to have a significant effect in terms of environmental benefits.

Different countries’ energy supplies and contrasting usage patterns are pushing manufacturers to expand their ranges and diversify according to local market conditions. As part of the Renault-Nissan Alliance, the Renault group intends to maintain its status as a worldwide market leader in the field of electric vehicles. PHEV (plug-in hybrid electric vehicle) solutions, such as that featured on EOLAB, complement this range and will be developed to suit widely differing driving patterns… but always with the goal of covering significant distances with “zero emissions”*.

2. TECHNOLOGICAL INNOVATIONS TO TAKE MOTORISTS EVER FURTHER

Without a constant stream of technological breakthroughs, the car’s environmental impact would diminish only through models gradually being replaced by others with cleaner internal combustion engines. In that respect, the pace of change is often linked to legislative changes affecting emissions.

This is why Renault thinks outside the box, offering ground-breaking technological innovations that are accessible to all. Firstly it has its all-electric vehicles, which emit no CO2 or other compounds from their exhausts, don’t create any smells and operate silently. Renault is the only manufacturer to offer a comprehensive range of four electric vehicles. Now, through its EOLAB project, Renault is extending zero-emissions mobility thanks to the development of an innovative hybrid system – Z.E. Hybrid – which allows users to cover trips of up to 60km* at speeds of up to 120km/h with absolutely no tailpipe emissions.

Zero-emissions mobility: an effective way to tackle poor air quality

According to a scientific modelling study of the Earth’s atmosphere, conducted using data from the city of Rome, achieving a 20 percent rate of zero-emission vehicles in the central traffic area would greatly reduce the concentration of pollutants that might be dangerous to our health. In the most polluted streets, calculations revealed a reduction of up to 30 percent for particles that cause respiratory or cardiovascular problems, and up to 45 percent for CO2, a significant respiratory irritant.

Alongside Renault’s existing range of four electric vehicles, the Z.E. Hybrid proposal is an effective new measure against this threat to public health.

* No CO2 or other regulated polluting emissions during road use.

EOLAB’S RECIPE

A weight saving of 400kg – Aerodynamic efficiency improved by 30% – Z.E. hybrid technology

The record fuel consumption achieved by the EOLAB prototype is the fruit of work in three fundamental areas:

Carefully-honed aerodynamics which achieved an improvement of 30%. EOLAB’s weight is around 400kg lighter than that of a B-segment hatchback like the Clio IV. In addition to benefiting from the above work, the Z.E. Hybrid powertrain is the sort of hybrid solution that will be seen on future Renault vehicles. Key figures:

A weight saving of 10kg equates to a CO2 saving of 1g/km (NEDC cycle) Aerodynamic efficiency: a reduction in drag (CdA) of 0.100m2 equates to a fuel consumption saving of 0.1 litres/100km (equivalent to 3.7g of CO2/km). EOLAB = a reduction of 0.170m2, a saving of 1.2 litres/100km on motorways (40g of CO2/km).

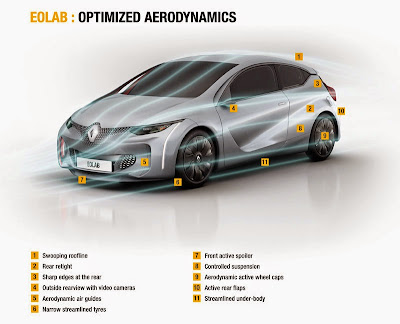

1. CAREFULLY HONED AERODYNAMICS WITH ACTIVE SYSTEMS

Drag coefficient (CdA) reduced by 30 percent

EOLAB’s CdA is 0.470m2 (A = 2.00m2 / Cd = 0.235) which represents an overall reduction of 0.200m² (around 30 percent). This lower drag coefficient results in a significant fuel consumption reduction at higher speeds. At a stable speed of 130kph, for example, it accounts for a fuel consumption saving of 1.2 litres/100km in comparison with the benchmark vehicle.

This exceptional aerodynamic efficiency was achieved by combining several factors:

Ground-breaking vehicle architecture, an innovative approach which includes a narrower rear track and a lower roofline without detracting from cabin space. Carefully designed rear body panels. Incorporation of active systems for even greater aerodynamic efficiency. NOTE: the measure of a vehicle’s overall aerodynamic efficiency is its CdA, i.e. the vehicle’s frontal section (A) expressed in square metres multiplied by its drag coefficient (Cd). The CdA of the Clio IV, for example, is 0.670m², which is a good average for its segment. However, CdA gains should not be achieved to the detriment of design considerations or other characteristics, such as cabin space.

Variable ride height

EOLAB’s ride height is variable thanks to the use of active air suspension. The four dampers can be raised or lowered by 25mm in relation to the default setting. When the car is parked, the suspension switches to its highest position in order to facilitate entry. As the vehicle begins to move, the suspension resumes its default setting (i.e. it lowers by 25mm) at speeds of between 5 and 70kph in order to limit the amount of air that passes underneath it. For the same reason, the ride height is lowered by a further 25mm at speeds in excess of 70kph.

Active spoiler

At the same time, the aerodynamicists focused on a variety of technological solutions and innovations. EOLAB’s front bumper, for example, is equipped with an active spoiler that lowers by 10cm at speeds in excess of 70kph in order to restrict airflow beneath the car. Even when a vehicle is designed with a flat underbody, there are still a number of asperities that can detract from aerodynamic efficiency.

Aerodynamic flaps

Another mobile feature of EOLAB’s aerodynamic package is the 40cm x 10cm vertically-positioned flaps that are visible on the rear bumper, rearward of the rear wheels. At speeds in excess of 70kph, these flaps open by 6cm in order to ensure that as much of the airflow as possible stays attached to the vehicle as it moves forward. Without this solution, passing air has a tendency to become detached from the vehicle’s sides too early after passing the rear wheels and this has a negative effect on drag. In the open position, airflow remains attached to the car as far rearward as possible, right to the trailing edge of the bumper. “These flaps tauten the airflow and prevent turbulence which otherwise acts as a sort of aerodynamic brake,” explains William Becamel, the aerodynamics expert who worked on the project.

Active wheels

The teams that worked on EOLAB took a close look at its wheels, too. In a perfect aerodynamic world, the rims would be covered and smooth. This is rarely the case, however, essentially for design- and brake cooling-related reasons. An ingenious system was consequently designed whereby the rims are covered whenever the brakes do not need to be cooled, thereby reconciling design and aerodynamic efficiency considerations. The system is controlled by a temperature sensor built into the rims.

Tyres that slice through air

To further perfect EOLAB’s aerodynamic performance, it is fitted with particularly narrow, 145mm-wide tyres. That’s 40mm narrower than the smallest tyres available for the Clio IV. Michelin and Renault’s designers worked on the tread pattern to give a visual impression of width, while the sidewalls were designed to exude an impression of light weight. At the same time, tyre supplier Michelin optimised the casing and tread to minimise rolling resistance while maintaining excellent levels of safety and performance. The tyres’ rolling resistance is 15 percent lower than those of the Clio IV which itself is quite strong in this area. These tyres are also lighter, and their profile has been honed to minimise drag. Meanwhile, Renault has changed the technology used for the wheel bearings in favour of a more efficient solution that has achieved a CO2 emissions saving of 1g/km.

(For further information, see appendix at the end of this document)

2. THE VIRTUOUS CIRCLE OF SAVING WEIGHT

EOLAB tips the scales at 955kg. That’s more than 20 percent lighter than the benchmark vehicle. Total weight savings amounted to no less than 400kg thanks to the teams’ holistic approach. This ambitious programme called for extensive work and outside-of-the-box thinking from the different specialists involved.

Body: 130kg saved, Trim and equipment: 90kg saved, Suspension: 70kg saved, Engine peripherals: 30kg saved, Powertrain: 60kg saved, Electrical equipment: 20kg saved, Z.E. Hybrid powertrain (including battery): 145kg added Total weight = 955kg

The virtuous circle of shedding weight

While delivering the same level of performance, lighter vehicles require less energy to move forward. One of the chief focuses in the case of the EOLAB project consequently consisted in reducing the vehicle’s overall weight. This in turn meant that the vehicle’s principle assemblies (powertrain, brakes, running gear, cooling system, fuel tank, etc.) could also be lighter, and these additional savings compounded the initial groundwork.

“The savings achieved by taking a fresh look at the size of the different mechanical assemblies enabled us to cover the cost of using more expensive materials and technologies elsewhere without losing sight of the aim not to add to the overall cost.” Laurent Taupin (EOLAB Project Leader).

Because it is lighter and more streamlined, EOLAB needs less energy to be moved forward. It was therefore possible to revise the amount of power necessary to drive it in order to arrive at a result that ensures running costs comparable with those of a current vehicle, without scrimping on acceleration performance. Equipped with a battery of just 6.7kWh (total energy), EOLAB permits zero emissions motoring* for a distance of 60km** at speeds of up to 120kph, a scenario which covers the majority of everyday needs.

* No CO2 or other regulated polluting emissions during road use.

** Consumption, emissions and range data homologated in accordance with appropriate legislation.

The right material for a given job

To reduce a car’s weight, a well-trod path is to replace steel with lighter materials. All-aluminium and aluminium/carbon solutions already exist but, in addition to the high cost associated with such materials, they often necessitate an in-depth review of assembly and production processes, and there is a price to pay for that.

True to its philosophy, Renault chose to steer clear of radical solutions. “You can always save weight if you’re prepared to pay the price, but that would be contrary to Renault’s philosophy. Our strategy is to reduce weight in a way that benefits everybody. That means finding economically viable solutions that our customers can afford. Our approach can be summed up by the phrase: ‘the right material for a given job’,” underlines the EOLAB Project Leader Laurent Taupin.

This undertaking to contain costs went hand-in-hand with a significant constraint, however, and that was to identify weight-saving solutions that are compatible with today’s production processes.

A lightweight multi-material body shell

Employing the right material for a given job involved conceiving an innovative body shell that combined different materials selected as a function of their weight, cost and necessary production processes. EOLAB’s body shell consequently combines steel, aluminium, magnesium and plastic composites, whereas the majority of today’s cars are made of a single type of material. 1. Steel: extensive use of Very Very High Elastic Limit steels (VVHEL) Over and above changes to a car’s basic architecture, the only way to lighten steel components is to use thinner metal. However, since detracting from a given part’s functional properties was out of the question, it was necessary to upgrade the mechanical properties of the steels employed at the same time. Renault consequently turned to Very Very High Elastic Limit steels which have a yield strength of between 1,200 MPa and 1,500 MPa, an improvement of between 200 MPa and 500 MPa over the VHEL steels used for current Renault models. With a tensile strength of up to 150kg/mm2, these grades were employed wherever their use served a real purpose, notably for the front part of the cabin. Their use requires a process known as hot stamping which Renault already uses for its production cars.

2. Aluminium

EOLAB’s highly innovative shell features a significant proportion of aluminium in different, readily available forms such as sheeting, castings and profiles. Like steel, upgrading the mechanical properties enables thinner grades to be used with no detriment to a part’s function but with an additional weight saving over conventional aluminium. Here again, these grades were selected in cases where it was possible to optimise the trade-off between function, mass, cost and the required manufacturing processes. Some of them necessitated a new warm stamping process (approximately 250/300°C, compared with hot stamping which is closer to 900°C) but this was compatible with existing stamp shop facilities.

All-aluminium circumferential chassis member

A combination of castings, sheet metal and profiles was chosen for EOLAB’s all-aluminium rear circumferential chassis member . Their use represented a good compromise between mass and body rigidity. Moreover, using the same material for this part of the shell was an attractive proposition in terms of thermal expansion. Indeed, body shells are exposed to temperatures of up to 180°C in the paint shop curing ovens and certain multi-material assemblies can have a negative impact on body shell’s geometry. Advantage was also taken of the use of cast parts of varying strength to cover multiple functions, that is to say the use of large, one-piece components to replace a number of smaller parts. This made it possible to compensate for the technology’s additional cost compared with conventional stamping.

3. A magnesium roof weighing just 4.5kg

While using steel and aluminium for a car body is itself not usual, Renault went further down this path in the case of EOLAB by making use of magnesium, too. This metal is reputed for its light weight (density: 1.7), but it is also prone to corrosion which is why it has only been used for interior components until now. Some cars already feature magnesium but only for moulded parts made from magnesium powder (e.g. the majority of the market’s steering wheel armatures).

EOLAB breaks new ground in the automobile industry by using magnesium sheeting. Developed thanks to the expertise of the specialist supplier POSCO, this innovation permitted the production of bulky items such as the roof, cowl panel and parts of the seat frames. The advantage is obvious, since EOLAB’s roof tips the scales at just 4.5kg, compared with 10kg for an equivalent steel roof. (For further information, see appendix at the end of this document)

“Magnesium sheeting cannot be used for as wide a range of parts as steel, or even aluminium. However, where the compromise between function, mass, cost and manufacturing processes allows, there are spectacular savings to be achieved, especially as the manufacturing process is the same as it is for certain new grades of aluminium, i.e. warm stamping,” points out Vincent Desmalades, Deputy Project Leader in charge of Processes.

4. The contribution of polymers

In order to cover as many realistic solutions as possible to minimise EOLAB’s weight, the project team also took a look at polymers which have long been reputed for their benefits in this area.

From thermoset to thermoplastic resins

Assisted by university laboratories and specialist suppliers, the team behind EOLAB worked on a new family of thermoplastic resins which are easier than thermoset resins to recover at the end of the vehicle’s life cycle and consequently recycle.

The demonstration car’s front, rear and central floor pans, B pillars and lower cross member are all made from hot-stamped composite thermoplastic, while the skins of the one-piece wings/bonnet assembly and doors are made from injection moulded thermoplastic. The type and proportion of the glass fibres mixed with these polymers vary as a function of the properties required for each end-use (e.g. longer fibres for structural components).

Reducing the weight of main assemblies

After attending to the body shell, EOLAB’s designers turned their focus to the car’s main assemblies which were all scrutinised with a view to saving weight. The brakes, steering, suspension, wheel and tyres were all looked at carefully to shave off kilogrammes without penalising their performance.

1. Lighter running gear

A vehicle’s running gear alone accounts for almost 20 percent of its weight (e.g. the Clio IV = 225kg). The most efficient solution involved replacing steel with aluminium for a significant number of heavy parts, such as the subframe, which has shed 5.3kg compared to that of the Clio IV (14kg), suspension arms (1.8kg saved), hub carriers (5kg saved) and rear arms (9kg saved). Substantial savings were achieved in this way, but EOLAB’s designers didn’t hesitate to explore other, more complex solutions. For example, they took a totally different approach to the architecture’s resistance to head-on impacts while maintaining the same overall level of safety performance. Normally, programmed chassis deformations affects three areas in an impact: the upper part of the chassis, the side members and the lower part of the chassis). In the case of EOLAB, the latter’s ‘add-ons’ were eliminated but this was compensated for by relocating and strengthening the side members. The resulting saving was between seven and eight kilos. “We also looked at making the springs from a glass fibre/thermoset plastic composite, which would have produced a saving of three kilograms. Using a different composite for the rear beam would have saved another three kilos or so, too,” notes Laurent Taupin.

2. Revised brake system

One might be forgiven for thinking that brake systems cannot make any sort of contribution to curbing CO2 emissions, yet they can. Indeed, reasonably big weight savings are to be made in this area. “EOLAB’s innovative brake system was developed in conjunction with Continental and points to the road down which Renault intends to go for its electric and hybrid vehicles in years to come,” says Laurent Taupin. For the same stopping performance, work on the brake system yielded a total saving of 14.5kg.

No fewer than three advanced innovations were developed in association with Continental. The most visible contribution was to suppress disc rub, whereby the brake pads remain in contact with the discs even when there is no pressure on the pedal. This constant rubbing adds slightly to fuel consumption. In the case of EOLAB, the pads do not touch the discs whenever the driver’s foot is off the pedal. In addition to being beneficial to fuel consumption, this also extends pad life. To maintain the same speed of response, and even improve it, EOLAB’s system eliminates slack by moving the pads closer to the discs the instant the system detects that the driver intends to apply the brakes.

Furthermore, the system’s new brake control unit has replaced the control units of several previously distinct functions (ABS, ESP, emergency brake assist) while allowing decoupled braking which is indispensable when it comes to recovering braking energy to reduce energy consumption. Meanwhile, the front brake discs have been lightened by combining steel and aluminium. The part of the discs in contact with the pads is made of steel, while the central part is made of aluminium. Also, since the body shell is lighter, it was possible to reduce the diameter of the discs for a total saving of 4.7kg.

A similar solution was employed for the rear drum brakes. The friction zone is still made of cast steel but the remainder of the drum is made of aluminium. The lighter rear brakes are more compact and equipped with more efficient bearings for a saving of 8.5kg.

Also in partnership with Continental, Renault took advantage of this arrangement to make the automatic parking brake act on the rear drums. This is more economical than the market’s existing system. Suppressing the manual mechanism (lever, cables, etc.) adds another 1.3kg to the total weight saving.

Shedding weight inside, too

1. Lighter glass

The EOLAB team also secured appreciable savings by reviewing the car’s glazing. Work to reduce the glass’s weight led to collaboration with Saint Gobain Sekurit with the aim of saving between 30 and 50% compared with present-day standards.

The thickness of EOLAB’s windows was reduced to 3mm (1.5mm less than the current norm), equivalent to the thickness of a pencil line. The thin windscreen, the form of which is particularly aerodynamic, is an automobile industry first. The side windows use laminated glass (instead of tempered glass), while certain non-moving windows make use of polymers which have become a widespread material for optical glass, but are still rarely seen in the car industry.

Lastly, the rear screen uses polymères vernis (instead of tempered glass). This technology made it possible to produce a one-piece polymère verni screen that also incorporates the rear lights. This solution serves as an eloquent example of how different functions can be grouped together to not only save weight but also enhance aerodynamic performance.

Combined, these solutions brought the total weight of EOLAB’s windows down to 21kg, a 25% saving over a Clio (28kg). (For further information, see appendix at the end of this document).

“We could have settled for existing processes or recipes for EOLAB, but that wouldn’t have been in the spirit of the project which has allowed us to extend our expertise. It has also focused the attention of the whole company on the issue of minimising weight without losing sight of production-related realties,” explains Laurent Taupin.

2. Thinner, lighter seats

EOLAB’s seats also came under the scrutiny of the car’s designers who not only endeavoured to make these generally heavy items lighter but also sought to make them slimmer to free up extra room for rear passengers.

To achieve these two objectives, Renault called on the expertise of the seat specialist Faurecia:

The thickness and weight of the front seats was notably reduced by using different materials for the frames (steel, non-ferrous alloys such as aluminium, carbon fibre composite and magnesium). The result was a 35-percent saving over the seat frame of a conventional B-segment vehicle. The cushion structure was optimised thanks to the use of a semi-rigid shaped trim and a compliant seat back. The resulting seat is 30 percent more compact, and this has freed up extra leg and knee room for rear passengers with no detriment to the comfort enjoyed by the front occupants who can still adjust the position of their seats. The seat shells were lightened thanks to Faurecia’s Cover Carving technology which consists in embedding a rigid 3D pattern onto a textile support to enable the cover to match the seat back’s forms as closely as possible. The use of this technology shaved 40 percent off the weight of the seat’s shell and provided rear passengers with three centimetres of extra room for their knees, legs and feet. 3. Using chemistry for lighter fittings

Close attention was paid to EOLAB’s smaller plastic fittings, such as the B-pillar trim. “These parts may only weigh a few hundred grams each, but they add up to about 10kg in the case of a production car if you include the boot lining,” points out Laurent Taupin. With input from suppliers, Renault’s specialists looked at alternative ways to make these plastic parts. One idea was to replace solid parts less than 2.5mm thick with parts comprising an ultra-thin skin (1.8mm) and injected with foam which is lighter because it contains air bubbles. Thanks to the incorporation of ribbing, they boast the same structural strength. Until now, this technique has been restricted to large visible parts or parts that customers cannot see. In the case of EOLAB, the challenge was to find a process that would be appropriate for smaller visible parts.

Meanwhile, for EOLAB’s boot trim, Renault used another experimental technique which again uses a sandwich structure comprising a foam insert between the two outer surfaces. This sandwich is obtained by slightly opening the mould during production to allow the foam to spread. Use of thinner fittings achieved a weight saving of between 20 and 30 percent.

4. Lighter than air

Meanwhile, plastics specialists took a close interest in the air intake ducts which are generally made of compact polypropylene and tip the scales at around 3kg. “Three kilos to channel airflow is too much,” believes Laurent Taupin.

The idea was therefore to replace this material with expanded polypropylene which is much lighter since its density is 0.06 compared with 0.96 in the case of compact polypropylene. However, if it had simply been a case of swapping one for the other, the switch would have been made a long time ago. In reality, it calls for duct walls that are five times thicker and that in turn means taking a fresh look at the car’s architecture. This is effectively what happened in the case of EOLAB and its ultra-light air ducts have been patented. They weigh just 700g, which is a spectacular saving of 2.3kg!

3. Z.E HYBRID: HYBRID TECHNOLOGY FOR ALL

In addition to being lightweight and aerodynamically efficient, the EOLAB demonstration car goes even further in its bid to achieve ultra-low fuel consumption thanks to its 100%-Renault hybrid powertrain which is covered by more than 30 patents. This technology consists in combining a petrol internal combustion engine (ICE) with a compact electric motor. This solution permits 60km** of zero emission* motoring plus extended range thanks to the internal combustion engine. Importantly, it can be carried over to entry-level vehicles which are by definition a more affordable reality for a higher number of motorists. This technology will be incorporated in the range by 2020.

* No CO2 or other regulated polluting emissions during road use.

** Consumption, emissions and range data homologated in accordance with appropriate legislation.

A motor inside the clutch housing

In the case of the EOLAB prototype, the ICE part of the powertrain takes the form of a small three-cylinder 999cc petrol engine with a power output of 57kW (75hp) and peak torque of 95Nm. It is mated to a highly innovative clutch-less transmission based on a compact and economical three-speed gearbox which is sufficient to cover the vehicle’s speed range. This is a notable advantage compared with the majority of the market’s hybrid technologies which make use of CVT- or DCT-type transmissions (Continuous Variable Transmission, or Dual Clutch Transmission). These tend to be bulky, heavy and costly, and consequently ill-suited to small cars.

The chief feature of the concept lies in the clutch casing which houses a permanent magnet electric motor (axial flux discoid motor in the case of the prototype). This motor is compact and economical and covers the need for the availability of extra torque since it is capable of instantly delivering peak power of 50kW and 200Nm of torque.

Fed by a 6.7kWh battery, it is sufficiently big to power the car under electrical power. Here again, the war waged on the weight of the body shell made a great deal of sense inasmuch as a lighter car needs less energy to be moved forward. As a consequence, the battery can be both smaller and less expensive.

Gearshifts for electric and ICE modes

It is important to note that the first two ratios of the three-speed gearbox are mated to the electric motor, while the third ratio is linked to the ICE. These three ratios permit nine different combinations for the electric and hybrid modes combined. One of the concept’s major innovations is the fact that gearshifts do not necessitate the use of a clutch thanks to a specific control unit designed by Renault’s engineers.

A battery suited to hybrid use

EOLAB’s axial flux permanent magnet electric motor is powered by a 6.7kWh lithium-ion battery which differs from the batteries that equip Renault’s Z.E. range of electric vehicles. While electric vehicles are designed to store a high amount of energy because of the fundamental need to maximise the vehicle’s range, hybrid vehicles like EOLAB need to cover the same power requirement with a limited quantity of electrical energy. This entails using a different type of battery cell with a higher power/energy ratio.

The resulting battery pack is the fruit of active cooperation between the teams at Renault and the CEA who rose to the challenge of finding smart solutions to come up with a battery pack that is capable of storing a high amount of energy in a smaller volume, while at the same time minimising weight.

Z.E. Hybrid… One mode for weekday use, another for weekends

A choice of two modes.

The ‘weekday’ mode favours the use of electrical power for everyday journeys (e.g. from the home to the workplace) in order to get as close to zero tailpipe emissions* and zero fuel consumption* as possible. EOLAB’s range is sufficient to cover 60km* under electrical power. When this mode is selected, the car always pulls away under electrical power and the first gear allows speeds of up to 60/70kph to be reached. At faster speeds, the system automatically engages the second gear and continues to run on electricity alone up to 120kph. Beyond this speed, the hybrid system automatically calls on the internal combustion engine which drives through the third gear. The ‘weekend’ mode combines both sources of power to permit longer travelling distances. Although the car still pulls away under electrical power, the internal combustion engine is engaged at a lower speed. The two power sources then combine, not only to use less energy but also to benefit from a real power boost thanks to the association of the ICE’s 90kW and the electric motor’s 50kW . In this mode, the battery charges under deceleration and braking (range saver function). The combination of the different gear ratios covers use up to the vehicle’s top speed in hybrid mode. This is a major concept that shows a way forward for hybridisation. “Today, most of the market’s hybrid vehicles are higher segment cars with a price tag of more than €40,000. The solutions showcased by EOLAB are much more economical and enable hybrid technology to be used for smaller cars and on a much bigger scale. Our objective is to produce a car with two power sources for the price of one,” underlines Jean-Pierre Fouquet, Z.E. Hybrid Innovation Project Leader.

** Consumption, emissions and range data homologated in accordance with appropriate legislation.

* No CO2 or other regulated polluting emissions during road use.

4. REAL-TIME INFORMATION CONTRIBUTING TO ULTRA-LOW FUEL CONSUMPTION

HMIs in favour of low fuel consumption and motoring enjoyment

Although Renault’s first hybrid vehicle – EOLAB – is packed with technologies and innovations, it is still aimed at the brand’s core customers, so had to remain easy to use and intuitive. It was also developed in keeping with Renault’s Driving eco² philosophy. At the same time, its Human Machine Interfaces (HMI) go even further down the road of providing information in real time with a view to helping drivers to benefit from ultra-low fuel consumption.

Its development was guided by three factors:

Visualisation of EOLAB’s technological features: the EOLAB demonstration car is equipped with aerodynamic features like an active front spoiler and active flaps which deploy at speeds in excess of 70kph. Intuitive: despite the car’s advanced technological content, the MMI was designed to be simple to use. “When a car targets a broad public, it is important that its use is easy to take on-board without having to read a manual that is dozens of pages long. In this respect, EOLAB follows the example set by R-Link which has received numerous accolades for its intuitive ease of use.” When technology takes centre stage

Given that on-board active systems are not visible from inside the vehicle and are only triggered at speeds or more than 70kph, the driver may feel a certain degree of frustration. Renault has endeavoured to avoid this issue by incorporating a specific function into the multimedia tablet which enables all of these systems to be activated and displayed whilst the car is at a standstill. “When an EOLAB-derived production car sees the light of day, it will not only be purchased out of economic motivation. Customers will also be attracted by its environmental and technological benefits. They will therefore want a ‘quantifiable return’, and this type of function will meet that requirement. Renault is keen to demonstrate that it is possible to drive an ultra-economical car whilst at the same time enjoying the experience,” underlines Rémi Bastien.

Instrument panel and multimedia display

In practice, the Human Machine Interfaces (HMIs) have been divided between two principal areas: the instrument panel and a touch screen multimedia display situated in a central position on the dashboard.

Height-adjustable instrument panel: The first original aspect is that this is not fixed. Courtesy of a mechanical arm, it moves in accordance with the height of the steering wheel that has been selected by the driver, in order to ensure optimum visibility.

Its content is spread across two digital displays the size of a smartphone: the one on the left provides all the technical information (speed, levels, conventional warnings), while right-hand side display is dedicated to the GPS. The upper part is utilised to display the image generated by the central rear-view camera. The lower part covers all of the multimedia system’s controls (radio, climate control, etc.).

A centrally-positioned touch screen display: All of the other functions are to be found on the touch screen display, allowing for the dashboard layout to be simplified, in-keeping with the spirit of EOLAB’s uncluttered design. The screen of this 11-inch tablet is divided into two parts. For the first time in the automotive world, the tablet can be fitted either horizontally or vertically, with distinct display graphics for each position. “In the vertical position, the accent is placed upon the sharing of information, which is easily visible to the other passengers. In its horizontal position, the screen is brought closer to the driver, generating a ‘cockpit’ effect, whilst the display graphics becomes warmer and more colourful,” explains Patrick Lecharpy. This unprecedented horizontal and vertical duality required specific studies and research to ensure that the two positions were compatible with the vehicle’s safety features, most notably its airbags.

Another noteworthy point: “With EOLAB being a hybrid vehicle, the drive mode is visible in an informative and educational manner on the tablet by way of cloud-shaped symbols that are blue when EOLAB is powered by its electric motor and turn red when the internal combustion engine takes over. What’s more, the size of these clouds varies according to the quantity of energy available in each mode,” reveals Patrick Lecharpy, the project’s design manager.

Putting drivers in charge of their energy consumption

Generally speaking, with energy consumption being at the very heart of the EOLAB concept, significant attention was paid to the presentation of related data. “As this is Renault’s first hybrid vehicle and an ultra-economical car, we really wanted the Human Machine Interfaces to permit a comprehensive understanding of the parameters that influence consumption, in order to assist drivers as they learn how to drive more economically,” indicates Laurent Taupin.

As a result, when the car is moving, the central tablet displays a ‘radar-style’ graphic whose five branches represent the five principal factors affecting the vehicle’s consumption:

Acceleration/braking (driving style) The car’s aerodynamics The gradient Tyre rolling resistance Use of electrically-powered equipment (notably thermal comfort) This graphic alters in real time according to the status of these five key parameters, thereby providing the driver with indications about how consumption may be improved in real time. “Today, after a fashion, the majority of the systems available in the market give drivers just raw information (current consumption, average consumption, etc.) that don’t really enable them to make any progress. Courtesy of this graphic, drivers now have at their disposal the necessary tools to take charge of their own consumption,” continues Jean-Pierre Fouquet, Z.E. Hybrid Innovations Project Leader.

INNOVATIONS FOR ALL

Towards a vehicle with ultra-low fuel consumption that is readily affordable

1. PERFORMANCE AND OWNERSHIP COSTS SIMILAR TO THOSE OF A CLIO-TYPE VEHICLE

Weight reduction, aerodynamic efficiency and hybridisation were three key themes that were explored with a common objective – that of developing realistic solutions that are transferable to mass-production cars. “Beyond the prototype, we need to make advances across the entire range,” affirms Project Leader Laurent Taupin. Similarly important to note is the fact that the lower fuel consumption figures have been achieved without impacting the vehicle’s performance in any way: “However efficient and economical it is, the vehicle must also remain competitive in every area if it is to attract buyers. This includes comfort, road holding, cabin space, perceived quality and design.”

In addition to the fact that it is based on a B-segment saloon, EOLAB was developed using a realistic technological and economic approach with a twofold objective:

To offer the same level of performance as a current vehicle. To be able to gradually carry the technological solutions spawned by EOLAB across to future Renault. Keeping costs under control!

When it comes to reducing weight, there is always the option of resorting to lightweight materials such as titanium, carbon-fibre or other composites, but in view of their expense, their wide-scale use would inevitably raise the price of the car. Such a scenario would be contrary to Renault’s very ethos, which is to make its cars available to the highest possible number of customers. What’s more, a very lightweight and expensive vehicle would remain something of a niche in commercial terms and, as such, would not generate any real benefits for the environment. EOLAB was developed with the target of producing a level of performance and price tag representative of a B-segment vehicle. The EOLAB project team thus paid careful attention to the key parameter of cost.

2. AROUND 100 TECHNOLOGICAL ADVANCES FOR FUTURE RENAULT MODELS

EOLAB packs around 100 technological advances, all developed through a mind-set of technological and economic realism. It consequently represents a basis for the design of future Renault vehicles.

Manufacturers have produced a number of projects to achieve ultra-low consumption over the course of the last three decades, but without the solutions found ever finding themselves applied to the vehicles they actually market. The reason for this is that they would have been too expensive and, therefore, not economically realistic.

With EOLAB, however, the process was different. All of EOLAB’s technological solutions were evaluated not only in terms of their capacity to reduce fuel consumption and CO2 emissions, but equally in a context of constraints relating to the real world in relation to production processes, technology and costs.

“We worked directly with the teams that develop Renault’s production cars, and they suggested new solutions to us in our quest for ultra-low fuel consumption. Not only did they propose these new solutions, but they also helped us to envisage what their implementation would signify on a larger scale. This project’s process of innovation is therefore already in-place for future vehicles in the Renault range,” observes Laurent Taupin.

A key criterion: compatibility with production facilities

At the heart of the EOLAB project is the prospect that all of the technological innovations developed as part of the process will be able to be transferred across to mass-production cars by 2020. This focus upon realism does not, however, signify that Renault is shirking away from envisioning more futuristic or avant-garde solutions. Quite simply, these were not (yet) necessary for this project, the aim of which was to reduce the CO2emissions of the brand’s range in either the short or medium-term. This pragmatic approach went hand-in-hand with a number of conditions of entry for the core technologies that are potential inclusions in EOLAB. Cost and feasibility are important considerations, but the primary concern is their compatibility with existing production facilities with limited investment.

The right balance between standard practices and innovation

Particularly close attention was paid to the question of manufacturing realism and the question came under the auspices of Vincent Desmalades, EOLAB’s Assistant Project Leader in this area. He explains that “the priority was to strike the right balance between two extremes: one the one hand, to reject everything that deviated from accepted standards, at the risk of no longer innovating, and on the other hand to openly give free rein to imagination and the unpredictable financial consequences that might entail”.

It was a balancing act that was not necessarily simple to achieve since one of EOLAB’s overriding guidelines was to design an extremely innovative multi-material body, combining steel, aluminium, magnesium, composites and injected thermoplastics – something that had never before been done in mass production. In order to establish the right positioning, the EOLAB team integrated production compatibility into the project’s mind-set from the very start.

That is firstly evident in the choice of materials and processes employed. The use of magnesium is a particularly eloquent example. It combines light weight with excellent production compatibility (hot stamping using existing facilities).

Next, it can be seen in the management of multiple materials. Even if welding is still widely practised, the multi-material body calls for new, complementary assembly processes. By dint of its strong multi-material compatibility and ease of implementation, bonding is the leading candidate amongst the modes of assembly that are currently under development.

Last but not least, it is perceptible in the area of industrial feasibility, which is vital to overall performance. This entails not only the feasibility of the core technologies involved and the availability of associated assembly processes, but also the co-existence of these technologies inside the manufacturing plants. This criterion is key in the quest to find the ideal compromise between the functions, weight, costs and necessary processes associated with the various technologies.

EOLAB CONCEPT : A CONCEPT CAR TO FIRE THE IMAGINATION

Design and Technology, Seduction and Efficiency

1. STYLING OF FLOWING, SENSUAL LINES

Alongside the EOLAB prototype, Renault is presenting EOLAB Concept, a second take on an ultra-low consumption vehicle, in the form of a concept car. Showing that efficiency can go hand in hand with appeal, this concept places particular emphasis on design, slotting into Renault’s design strategy with simple, warm and sensual lines conveying a strong sense of emotion. It belongs on the sixth petal of the life cycle daisy, representing Wisdom (understanding, an open mind, serenity). Some of the design features of EOLAB Concept prefigure trends that could find their way onto production models.

Design and aerodynamics on a par

Aerodynamic and appealing, compact but spacious, high-tech but not utopian, EOLAB Concept expresses and embodies the qualities seen on EOLAB prototype, taking them to new heights. Like a haute couture version placed alongside an off-the-peg model.

EOLAB Concept was inspired by the prototype but it takes the design to a new level. All the fundamentals of the prototype are maintained in terms of aerodynamics, proportions and interior space, with the features expected of a B segment car. EOLAB Concept is a realistic vehicle, shown in its best light. This is because, in order to fully express the concepts of aerodynamics and lightweight construction, designers simply took the car’s ideal lines and attention to detail a little further. Even when it is subject to strict design constraints, in pursuit of very low consumption, concept cars must still capture the imagination.

Patrick Lecharpy, Vice-President, LCI (see insert) and Alliance Synergies, tells us how the duo came about: “A technology demonstrator is rarely attractive. And a concept car is rarely realistic. That’s why we decided to develop two vehicles as part of this project. The concept car emphasizes the visual aspects of the demonstrator and seeks to take design solutions a bit further under the final authority of the design department, while the prototype design came under the authority of the engineering department. The aim was for technology and desirability to go hand in hand, to avoid a result that would be high-tech but cold.”

EOLAB Concept is therefore a unifying symbol, expressing high-tech innovation at Renault while fully reflecting the brand’s design strategy.

LCI, a start-up within the company, bringing together engineers and designers

The Cooperative Innovation Laboratory (LCI) is an independent structure operating within Renault. The aim of brand management was to set up a creative entity with a collaborative function, grouping engineering, product and design staff in the same working space. This original organization has spawned a dynamic and creative entity, able to respond to needs quickly. A real wellspring of new ideas. Made up of around forty people, “LCI is a bit like a start-up inside a major company. Conditions are ideal for developing innovations and breakthrough concepts,” explains Patrick Lecharpy.

Each project has four key ingredients: design, technology, economic constraints and customer surveys. LCI develops a wide range of projects and enjoys considerable leeway in its work: one-third of projects are the result of discussions with external players such as parts suppliers and specialist schools, the aim being to step outside the framework of conventional programs and create a fertile ground for completely original ideas. To give just one highly eloquent example: Renault Twizy was based on the work of LCI.

With its flexible, dynamic organization, LCI is able to move quickly from conceptual ideas to physical reality (design mock-ups, prototypes, etc.). This enables fast decision-making on a practical basis. A force for the company, this entity also highlights the nature of innovation at Renault.