The Volkswagen Group to unveil its first diesel plug-in hybrid; Aston Martin announces DB10 for new James Bond film.

The Volkswagen Group to unveil its first diesel plug-in hybrid; Aston Martin announces DB10 for new James Bond film. Tesla Model S Beats Porsche in Owner-Satisfaction Survey

Tesla drivers were more likely than Porsche owners -- or anyone else -- to say they’d buy their cars again in this year’s edition of the closely watched Consumer Reports buyer survey.

Tesla’s Model S luxury electric sedan topped the U.S. survey a second year in a row, scoring 98 out of a possible 100, after posting a 99 last year. This year’s No. 2 brand, Porsche, scored an average of 87 out of 100 across its model lines. Palo Alto, California-based Tesla, co-founded and led by billionaire Elon Musk, said last month that it expects to sell 50,000 Model S cars next year.

“Not only is the Tesla roomy, comfortable, and a lot of fun to drive, but it also has low operating costs,” Consumer Reports said.

The survey will bolster the 11-year-old carmaker’s image as the leader in the business of making high-end electric cars. Tesla plan to expand sales of the Model S and develop the long-awaited Model X SUV, which is expected in the third quarter of 2015. Tesla stock has gained 52 percent this year.

Sports Cars

The next three most satisfying vehicles in the Consumer Reports Survey, after the Model S, were sports cars: General Motors Chevrolet Corvette Stingray, with a 95 percent satisfaction rating, and Porsche Cayman and Boxster, which tied for third with 91 percent of buyers saying they’d purchase them again.

The survey covered 350,000 vehicles from one to three years old and took into account “attributes such as styling, comfort, features, cargo space, fuel economy, maintenance and repair costs, overall value, and driving dynamics,” Consumer Reports said.

Hybrid, electric and diesel-powered cars outscored gas engines throughout the survey, with the Chevrolet Volt and Toyota Prius leading the compact-car category and Honda Accord Hybrid and Ford's Fusion Energi atop the list of mid-sized sedans.

Wheelies: The Buon Anniversario, Maserati Edition

Germany to Boost Incentives in Push for 1 Million Electric Cars

Chancellor Angela Merkel said Germany will need to provide more incentives to meet a goal of having 1 million electric cars on the country’s roads by 2020.

“There’s a lot to do,” Merkel said today during a press conference in Berlin. “We see that further subsidies are necessary. We must speak with the German states about that.”

Merkel is far behind in her push for 1 million electric autos in part because her government has balked at incentives like those offered in France, where consumers receive as much as 6,300 euros ($7,840) to help cover the higher cost of low-emission vehicles. Germany, which has about 24,000 electric autos on its roads, is considering offering a tax break for zero-emission vehicles sold as company cars.

“We’re far from our goal to establish Germany as a leading market for electro-mobility,” said Matthias Wissmann, president of German auto-industry lobby VDA. “The government needs to act” on plans such as the corporate tax reduction.

The chancellor is trying to reduce emissions by pushing the country’s auto industry to build more electric cars after French, Japanese and American carmakers got off to an early lead. German auto manufacturers will offer 17 electric models by the end of 2014, and another 12 will go on sale next year, according to the VDA.

Charging Stations

Merkel’s cabinet announced plans in September to offer electric-car buyers special privileges, backing a bill that would enable municipalities to offer drivers of battery-powered cars, fuel cell vehicles and some plug-in hybrids free parking and the right to use bus lanes.

The country has 4,800 charging stations, said Henning Kagermann, a former chief executive officer of software maker SAP who is heading the government’s electric-car effort. Transport Minister Alexander Dobrindt said Germany will add 400 stations at rest stops along the autobahn network to make it possible to travel across the country with electric vehicles.

“We need a super-charger infrastructure where you can charge 80 percent of the battery in 15 minutes,” said Stefan Bratzel, director of the Center of Automotive Management at the University of Applied Sciences in Bergisch Gladbach, Germany. “The government can help to establish standards for plugs to make the charging stations accessible for vehicles of all brands. We’re still very much in the wild electro-west.”

BMW i3

Zero emission vehicles from German automakers include Bayerische Motoren Werke AG’s i3 city car as well as electric versions of Daimler AG’s Smart two-seater and Mercedes-Benz B-Class. Volkswagen AG sells the Up! and Golf with electric motors. The offerings follow the entry into the market of Tesla Motors Inc.’s S Model, Nissan Motor Co.’s Leaf and General Motors Co.’s Volt.

Germany was a transport pioneer when it opened Europe’s first car-only highway in 1921 in Berlin. Its free-wheeling autobahn, which often doesn’t have a speed limit, has spurred a motoring culture, helping BMW, Mercedes and and VW’s Audi and Porsche brands to dominate the market for high-end cars.

The government announced plans today for a conference next summer in Berlin to discuss how the country can make further progress in electro-mobility.

BMW i8 vs BMW M1 track battle [VIDEO]

The new BMW i8 is a futuristic stunner, with a hi-tech duo of an electric motor and petrol engine from the MINI Cooper. Jump back more than three decades and the last mid-engined car to wear a BMW badge was the M1 - which turned just as many heads when it debuted in 1978.

To find out how thirty years of evolution has changed the BMW supercar, Auto Express took along a classic M1 to meet the new i8 at the test track. The BMW i8 features a 1.5-litre three-cylinder turbocharged petrol from the MINI Cooper driving the rear wheels, while an electric motor drives the front. Under the engine cover of the M1 is something altogether much more traditional: a 3.5-litre six-cylinder unit putting out 277bhp and 330Nm of torque. This compares to 357bhp and 570Nm in the i8.

On the track, the two cars feel very different. The M1 wasn't pushed too hard due to its age and value - mint examples fetch around £400,000 - but it performed brilliantly around the track. The gearbox has lovely action, the steering is perfectly weighted and the chassis feels perfectly matched to the power on tap.

Jump into the i8 and it feels very futuristic. There's instant power on tap due to the combination of the electric motor and the engine in Sport mode, with a great soundtrack in the cabin - it's even reminiscent of the sound of the M1. There's plenty of grip, too, and the performance is great. It's rather special and doesn't feel like any other BMW.

Both the i8 and M1 are true BMWs at heart. It's not often that BMW breaks the mould and builds a mid-engined car, but when they do, they know how to make their mark.

Stohl Racing reveal Peugeot 207 S2000 AWD Electric Rally Car

Stohl Racing surprised at the Motor Show in Essen. The Austrians transplant two electric motors in a Peugeot 207 S2000 and have been approved for use in special stage rallying.

The Peugeot S2000 built by Manfred Stohl is all-wheel-drive via 2x electric motors with a maximum output of 400 kW (544 hp), more impressive is the torque of a whopping 880 Nm which, typical of electric motors, comes on immediately. Zero to 100 km/h takes only 3.0 seconds despite a weight of 1,500 kg.

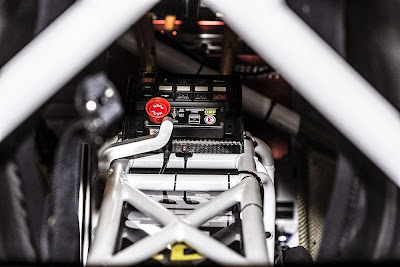

A highlight is the installation of the battery, which is located between the driver and passenger. This is installed in a special cage construction, but can be changed in service in just five minutes. This is made possible through a specially designed trailer mounted lift.

The range of the electric-S2000 as usual depends on the driving style. Stohl Racing has calculated approx 30 kilometers range with a subsequent return to the Service to change the battery. The rally-e Stohl Mk1 will premiere in the state rally championship soon.

BMW Plans to Roll Out Plug-in Versions for Its Top Cars

BMW plans to offer plug-in hybrid versions of all its main models, including the best-selling 3-Series sedan, as the world’s largest maker of luxury vehicles reacts to tighter emissions regulations.

Carmakers are adding electric motors to improve fuel efficiency and make their vehicles viable in cities like London, which has set up a low-emission zone to improve air quality. Plug-in hybrids have batteries that can be recharged from electrical outlets and can drive emission-free for longer distances than conventional hybrids.

BMW is presenting a prototype of a plug-in hybrid 3-Series today in Miramas, France, the company said in a statement. The car combines a four-cylinder gasoline engine with an electric motor and can drive about 35 kilometers (22 miles) on battery power.

The German carmaker also plans to roll out a plug-in hybrid version of its X5 sport-utility vehicle and other “core-brand” models, according to the statement. Electric versions from the Mini and Rolls-Royce brands are also “a possibility,” said Manfred Poschenrieder, a spokesman for the Munich-based company.

Bayerische Motoren Werke AG (BMW) created the ‘’i’’ sub-brand for showcasing its clean-car technology and safeguarding its image as a maker of sporty vehicles. The first cars from the BMW i unit were the i3 battery-powered city car and the i8 plug-in hybrid super car. The company didn’t specify a timeframe for rolling out plug-in hybrid versions of its models.

Daimler to spend 100 million euros to expand German battery output

Daimler will spend about 100 million euros (US$125 million) in coming years to increase production of lithium-ion battery packs in eastern Germany.

The German automaker said on Monday it will expand capacity at Deutsche ACCUmotive, its battery-making division in Saxony as it expects "high and steadily-growing demand" for electric-car batteries.

The unit supplies batteries for the luxury Mercedes division's hybrid S-Class, E-Class and C-Class models, Daimler said.

Steps to increase battery output tie in with Daimler's plans announced last month to phase out production of lithium-ion battery cells at its second Saxony-based Li-Tec division by the end of 2015.

Daimler aims to employ the bulk of Li-Tec's 250 workers at Deutsche ACCUmotive.

The Stuttgart-based manufacturer in future plans to buy battery cells from LG Chem.

Asian makers of battery cells such as Samsung, Panasonic and LG Chem are producing the cells at lower costs, reaping benefits from scale effects as they're also serving non-automotive industries, analysts said.

Volvo hybrid bus with Siemens fast-charging system starts service in Hamburg

Officially launched at the International IAA Commercial Vehicles show, the Volvo 7900 Electric Hybrid buses equipped with a Siemens fast charging systems has taken its maiden tour in Hamburg, where it will be deployed from December on the 109 service.

“Battery technology is becoming increasingly attractive for use in buses. The electric hybrid bus is an important further step for us on the way to procuring 100% electric buses. Hochbahn sees itself as industry's partner in gathering important experience in everyday service,” said Ulrike Riedel, vice president for operation and human resources at public transport operator Hamburger Hochbahn.

The Volvo 7900 Electric Hybrid has an electric hybrid powertrain that combines a four-cylinder diesel 240 hp (177 kW) with an electric motor of 150 kW. The latter receives energy from a lithium ion battery of 19 kWh total storage capacity, this allows travel in electric mode a distance of 7 km between charges.

The lithium-ion battery is charged via two charging rails on the roof. Fast charging stations have been set up next to the route with a contact arm fastened to a mast. If the bus is with range of the contact system, the drive operates the parking brake and charging will start automatically. Charging is performed fully automatically and ends as soon as the charging is fully completed. The process also can be cut short by releasing the parking brake.

The fast charging stations in Hamburg are the latest development from Siemens for high-performance charging systems for electric buses. On the buses, it is only necessary to mount contact rails and a WiFi communication box. That saves space, weight, and costs on each bus. Communication between the bus and the charging station is established by WiFi. In this way, the bus is identified and the requirements of the battery management system are transmitted to the charging station. To make contact, the contact arm is lowered onto the charging contacts on the bus. The bus is electrically grounded before current starts to flow. The flow of current between the vehicle and the charging station is controlled continuously and matched to the individual charge state and battery type. The charging operation is completed in no more than six minutes.

World Record holders Sunswift launch Pozible to fund refit of car for road registration

UNSW’s solar racing team Sunswift has launched a crowd-funding campaign to raise money to rebuild their car for Australian road registration.

The eVe vehicle, which recently smashed a 26-year-old world record for the fastest electric car over 500 km, is seen as a symbol for a new era of sustainable driving. It is covered in zero-emission solar panels and uses a battery storage system that can be charged with the solar cells or by plugging the car into a power outlet.

The world record proved the car is technically capable of covering the maximum distance a normal road user might want to drive in a single day.

The next step in the Sunswift journey is to put eVe within reach of the average driver by converting it from concept car to road-registered coupe.

The team of 60 undergraduate students behind Sunswift is aiming to raise $30,000 – about one-third of the amount they need – using the crowd-funding site Pozible. They plan to source the remaining money and components via sponsors and in-kind contributions from industry partners.

If successful, it will mark the first time a university solar car team has built a vehicle to the stringent standards of the Australian Design Rules – the national motoring standards that govern vehicle safety, anti-theft and emissions.

“Full registration is no humble feat with essentially the whole car needing to be deconstructed and rebuilt,” says project director and engineering student Hayden Smith.

“The car requires front, rear and side impact protection, headlights, windscreen wipers, new raised suspension and new wheels in addition to updated electrical components.

“The interior will also be redesigned to meet safety regulations and offer a level of comfort that would be expected from a commercial car.”

Coinciding with its latest fundraising push, the team has set an ambitious goal of achieving road registration as early as March 2015.

“Having solar cars conquer the roads would mark a huge leap in the race to develop more sustainable transport alternatives, showcasing their potential to be commercialised in the near future,” Sunswift’s chief business officer and student Rob Ireland says.

"However, we can't change the world by ourselves so we're asking for help to make it happen."

Supporters who contribute to the crowd-funding campaign will be offered rewards including 3D printed models of the car, solar cell mantlepiece trophies and one-time advertising space during PR events. The campaign begins on Monday 1 December.