Elon Musk of Tesla Sticks to Mission Despite Setbacks

GM Buying 3 yo Self-Driving Tech Startup for $1 Billion

General Motors announced Friday it is buying Cruise Automation, a San Francisco self-driving vehicle startup, the latest move by the auto company as it competes with Silicon Valley to develop self-driving cars that could be used in ride-sharing fleets.

GM and Cruise did not disclose the value of the deal. Technology website Re/Code cited sources as saying GM paid $1 billion. A GM spokesman declined to comment on that figure. If correct GM has just set a new precedent for valuations of automotive tech start-ups.

GM intends to use Cruise’s technology and people to accelerate its effort to develop vehicles that can operate without a human driver, potentially as part of ride-sharing fleets “as soon as possible,” GM President Dan Ammann said in an interview.

“We will be committing considerable resources to recruit and grow the capability of the team,” Ammann said.

Cruise has been working to develop hardware and software that could be installed in a vehicle to enable the car to pilot itself on a highway, without the driver steering or braking.

GM initially planned an investment in the company but moved within five weeks to buy Cruise outright, said venture partner Nabeel Hyatt of Spark Capital, an investor in Cruise.

"They moved faster than most Silicon Valley companies would move," he said.

Cruise, which has 40 employees, was launched in 2013 and has raised $20 million in venture capital, founder Kyle Vogt said in an interview.

Vogt impressed Silicon Valley venture capital fund Signia Venture Partners by demonstrating an Audi A4 that could be controlled by a game console, said Signia principal Sunny Dhillon.

More recently, Cruise was working on a system that could make a car "fully driverless," Vogt said.

A flurry of investments by traditional auto companies reflects a fear among industry executives that the century-old business of building and selling cars that people drive themselves is at risk, even though global vehicle demand is strong.

In January, GM said it would invest $500 million in ride-hailing company Lyft Inc and followed that by forming a new car-sharing operation called Maven. The company has also established a separate unit for self-driving vehicle development.

Other automakers are moving into ride sharing and self-driving vehicles, as are some traditional auto suppliers.

Germany’s Continental and Delphi Automotive among others are seeking technology companies to buy for intellectual property and programming talent.

Drive Unit and Battery at Heart of Chevrolet Bolt EV [VIDEO]

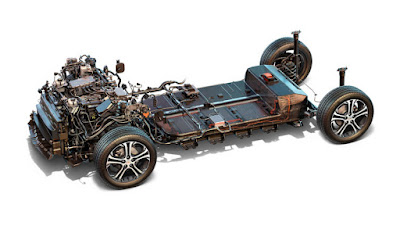

The 2017 Chevrolet Bolt EV does more than set a new benchmark for affordable, long-range EV driving. It also raises the bar when it comes to driving performance.

Engineers developed the Bolt EV’s propulsion system to offer more than an estimated 200 miles (based on GM estimates) and a peppy driving experience that’s more akin to a compact sports sedan than a small utilitarian crossover.

“Being the leader in range and affordability means nothing if the car isn’t going to excite you each time you get behind the wheel,” said Josh Tavel, Chevrolet Bolt EV chief engineer. “That’s why the team was tasked with delivering a propulsion system that would also make the Bolt EV an electric vehicle that owners would love to drive.”

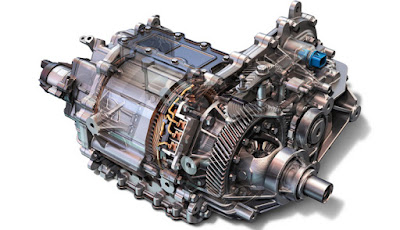

Single Motor Drive Unit

Like most EVs on the road, the Bolt EV’s drive system uses a single high capacity electric motor to propel the car. But it’s the smooth, powerful and quiet motor design, gear configuration and shift-by-wire system that separates it from the pack.

The engineering team designed the Bolt EV’s electric motor with an offset gear and shaft configuration tailored to meet efficiency and performance targets – most notably more than an estimated 200 miles of range. The motor is capable of producing up to 266 lb.-ft. (360 Nm) of torque and 200 hp (150 kW) of motoring power. Combined with a 7.05:1 final drive ratio, it helps propel the Bolt EV from 0-60 mph in less than seven seconds.

Power delivery is controlled by Chevrolet’s first Electronic Precision Shift system. This shift and park-by-wire system sends electronic signals to the Bolt EV’s drive unit to manage precise feel and delivery of power and torque, based on drive mode selection and accelerator inputs. A by-wire shifter requires less packaging space than a traditional mechanical shifter, resulting in more interior space and improved interior layout.

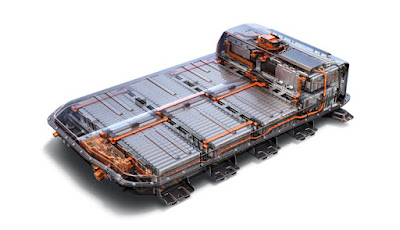

60 kWh Battery System

Having more than 1.3 billion miles of EV experience from the Chevrolet Volt helped Bolt EV battery engineers and strategic partner LG Electronics to develop an all-new cell and battery pack to offer more than an estimated 200 miles of range.

Battery system preliminary specifications include:

“You usually have a battery cell that delivers either the desired levels of energy or power, but not traditionally both. With this cell design and chemistry we were able to deliver a battery system with 160 kilowatts of peak power and 60 kilowatts hours of energy,” said Gregory Smith, Bolt EV battery pack engineering group manager.

The battery uses active thermal conditioning, similar to the Chevrolet Volt, to keep the battery operating at its optimum temperature, which results in solid battery life performance. The Bolt EV battery will be covered by an 8-year/ 100,000 mile (whichever comes first) limited warranty.

Inside the battery pack – which spans the entire floor, from the front foot well to back of the rear seat – is a new cell design and chemistry. The nickel-rich lithium-ion chemistry provides improved thermal operating performance over other chemistries, which requires a smaller active cooling system for more efficient packaging. The chemistry allows the Bolt EV to maintain peak performance in varying climates and driver demands.

The cells are arranged in a “landscape” format and each measures in at only 3.9 ins. (100 mms) high and 13.1 ins. (338 mms) wide providing improved packaging underfloor. The lower profile cell design enabled the vehicle structure team to maximize interior space.

The battery system is mated to a standard equipment 7.2 kW onboard charger for regular overnight charging from a 240-V wall box. A typical commute of 50 miles can be recharged in less than two hours. Bolt EV also features an optional DC Fast Charging system using the industry standard SAE Combo connector. Using DC Fast Charging, the Bolt EV battery can be charged up to 90 miles of range in 30 minutes. Outside temperatures may affect charging times.

Regen System Provides One-Pedal Driving

Regenerative braking has become more than just a tool to boost range, it’s also transformed into a feature that can provide an improved EV driving experience. The Bolt EV features a new regenerative braking system that has the ability to provide one pedal driving.

“Interviews with EV enthusiasts indicated their desire for one pedal driving capability on the Bolt EV. One pedal operation boosts the thrill and uniqueness of EV driving,” Tavel said.

Through a combination of increased regenerative deceleration and software controls, one pedal driving enables the vehicle to slow down and come to a complete stop without using the brake pedal in certain driving conditions.

When operating the Bolt EV in “Low” mode, or by holding the Regen on Demand paddle located on the back of the steering wheel, the driver can bring the vehicle to a complete stop under most circumstances by simply lifting their foot off the accelerator, although the system does not relieve the need to use the brake pedal altogether.

Operating the Bolt EV in “Drive” mode and not pulling the paddle while decelerating delivers a driving experience where usage of the brake pedal is required to stop.

Chevrolet Bolt EV specs released

Hard on the heels of the reveal of the production Volt EV at CES 2016 in Las Vegas, Chevrolet used the North American International Auto Show in Detroit to release additional details on the battery and drivetrain of the new BEV. Engineers developed the Bolt EV’s propulsion system to offer more than an estimated 200 miles and a sporty driving experience.

The Bolt EV’s drive system uses a single high capacity electric motor to propel the car. The engineering team designed the Bolt EV’s electric motor with an offset gear and shaft configuration tailored to meet efficiency and performance targets—most notably more than an estimated 200 miles of range. The motor is capable of producing up to 266 lb-ft (360 N·m) of torque and 200 hp (150 kW) of motoring power. Combined with a 7.05:1 final drive ratio, it helps propel the Bolt EV from 0-60 mph in less than seven seconds.

Power delivery is controlled by Chevrolet’s first Electronic Precision Shift system. This shift and park-by-wire system sends electronic signals to the Bolt EV’s drive unit to manage precise feel and delivery of power and torque, based on drive mode selection and accelerator inputs. A by-wire shifter requires less packaging space than a traditional mechanical shifter, resulting in more interior space and improved interior layout.Having more than 1.3 billion miles of EV experience from the Chevrolet Volt helped Bolt EV battery engineers and strategic partner LG Electronics to develop an all-new cell and battery pack to offer more than an estimated 200 miles of range. Battery system preliminary specifications include:

Inside the battery pack—which spans the entire floor, from the front foot well to back of the rear seat—is a new cell design and chemistry. The nickel-rich lithium-ion chemistry provides improved thermal operating performance over other chemistries, which requires a smaller active cooling system for more efficient packaging. The chemistry allows the Bolt EV to maintain peak performance in varying climates and driver demands.

The cells are arranged in a “landscape” format and each measures in at only 3.9 ins. (100 mms) high and 13.1 ins. (338 mms) wide providing improved packaging underfloor. The lower profile cell design enabled the vehicle structure team to maximize interior space.

The battery system is mated to a standard equipment 7.2 kW onboard charger for regular overnight charging from a 240-V wall box. A typical commute of 50 miles can be recharged in less than two hours. Bolt EV also features an optional DC Fast Charging system using the industry standard SAE Combo connector. Using DC Fast Charging, the Bolt EV battery can be charged up to 90 miles of range in 30 minutes. Outside temperatures may affect charging times.

Regen System Provides One-Pedal Driving. Regenerative braking has become more than just a tool to boost range, it’s also transformed into a feature that can provide an improved EV driving experience. The Bolt EV features a new regenerative braking system that has the ability to provide one-pedal driving.Through a combination of increased regenerative deceleration and software controls, one pedal driving enables the vehicle to slow down and come to a complete stop without using the brake pedal in certain driving conditions.

When operating the Bolt EV in “Low” mode, or by holding the Regen on Demand paddle located on the back of the steering wheel, the driver can bring the vehicle to a complete stop under most circumstances by simply lifting their foot off the accelerator, although the system does not relieve the need to use the brake pedal altogether.

Operating the Bolt EV in “Drive” mode and not pulling the paddle while decelerating delivers a driving experience where usage of the brake pedal is required to stop.

Overview

Model: | Chevrolet Bolt EV |

Body style / driveline: | front-wheel-drive, five-passenger, five-door all-electric CUV |

Construction: | Steel and Aluminum |

EPA vehicle class: | Small Wagon (EPA does not have a cross-over category) |

Key competitors: | Nissan Leaf, BMW i3, Ford Focus Electric, Kia Soul EV, VW eGolf Mercedes-Benz B-Class Electric |

Manufacturing location: | Orion Township, Mich. |

Battery manufacturing location: | Incheon, South Korea |

Motor and drive unit manufacturing location: | Incheon, South Korea |

Battery System

Type: | rechargeable energy storage system comprising multiple linked modules |

Volume/case: | 285L |

Mass (lb / kg): | 960 lb./435 kg |

Battery chemistry: | lithium-ion |

Thermal system: | liquid active thermal control |

Cells: | 288 |

Electric driving range: | More than 200 miles (GM estimate pending final tests) |

Energy: | 60 kWh |

Warranty: | eight years / 100,000 miles |

Electric Drive

Type: | Single motor and gearset |

Motor: | permanent magnetic drive motor |

Power: | 200 hp/150 kW |

Torque: (lb-ft / Nm): | 266 lb.ft./360 Nm |

Final drive ratio (:1): | 7.05:1 |

Charging Times

120 V: | Available with standard cordset |

240 V: | 50 miles of range in less than 2 hrs. |

SAE Combo DC Fast Charge: | 90 miles in 30 minutes |

Performance

Top speed (mph): | 91 mph / 145 kph * |

0-30 mph: | 2.9s (75% SoC) * |

0-60 mph: | Under 7 seconds |

Chassis/Suspension

Front: | Independent MacPherson strut-type front suspension with side load compensating and finely tuned springs, direct-acting solid stabilizer bar system and ride & handling oriented LCA bushings. |

Rear: | Compound crank (torsion beam) type rear suspension with the closed section V-shaped profile axle; specifically tuned coil springs, performance balanced shock absorber, angled A-bushing supporting understeer tendency on cornering maneuver and kinematically optimized torsion beam providing stable and best ride & handling performance. |

Chassis control: | Four-channel ABS; Traction control system; StabiliTrak; Drag control |

Steering type: | column-mounted electric power steering |

Steering wheel turns, lock-to-lock: | 2.91 revolution * |

Turning radius, curb-to-curb ( ft. / m): | 10.8m * |

Steering ratio: | 16.8 :1 |

Brakes

Type: | power four-wheel disc with ABS; electro-hydraulic; partially regenerative; dynamic rear brake proportioning |

Brake rotor diameter front (mm / in): | 276mm |

Brake rotor diameter rear (mm / in): | 264mm |

Total swept area (cu cm): | Front : 1398.9 Rear : 1131.4 |

Wheels/Tires

Wheel size and type: | 17in x 6.5J offset 44, cast aluminum |

Tires: | Michelin Energy Saver A/S 215/50R17 all-season |

Dimensions

Wheelbase (in / mm): | 102.4 / 2600 |

Overall length (in / mm): | 164.0 / 4166 |

Overall width (in / mm): | 69.5 / 1765(W103) |

Track width front (in / mm): | 1500.92 mm |

Track width rear (in / mm): | 1501.05 mm |

Height (in / mm): | 62.8 / 1594(H100) |

Front overhang (in / mm): | 32.9 / 836 |

Rear overhang (in / mm): | 28.7 / 730 |

Seating capacity (front / rear): | 2 / 3 |

Headroom (in. / mm): | 39.7 / 1009 1st row 37.9 / 962 2nd row |

Shoulder room (in / mm): | 54.6 / 1387 1st row 52.8 / 1340 2nd row |

Hip room (in / mm): | 51.6 / 1310 1st row 50.8 / 290 2nd row |

Legroom (in / mm): | 41.6 / 1056 1st row 36.5 / 927 2nd row |

Cargo volume (cu ft / L): | 16.9 cu-ft / 478 L (V10, Wagon CVI – Max behind rear seat) |

Passenger volume (cu ft / L): | PV1 52.2 cu-ft / 1478 L 1st row PV2 42.2 cu-ft / 1195 L 2nd row |

Capacities

Curb weight (lb / kg); | 3580 lb / 1625kg based on target (w/o 2passengers) |

Heating cooling (qt / L): | Heating loop 1.8L |

Battery pack cooling (qt / L): | 6.9L (RESS cooling loop total coolant volume) |

Power electronics cooling (qt / L): | 3.9L (PE & DU cooling loop total coolant volume) |

Drive unit fluid (qt / L): | 2.9L |

Chevrolet Bolt battery cells to cost “industry-leading” $145 per kWh

General Motors told Wall Street on Thursday that when it introduces the 2017 Chevrolet Bolt small electric car next year, it expects the cost of its battery cells to be an "industry-leading" $145 per kWh.

The electric vehicle market has been pressured by low fuel prices in 2015. A lowering of the costs of EV battery cells to $100 per kilowatt-hour by 2022 will allow EVs to compete with vehicles fueled by petroleum.

LG Chem CFO Cho Suk-jeh last year revealed the company will supply an automaker with a battery that will allow one of their models to travel more than 200 miles (320 km) on a single charge but declined to say which automaker. Although all indications point to LG Chem supplying the Bolt battery, GM do have other options.

In competition with firms like Bosch and Volkswagen, General Motors, via their GM Ventures subsidiary, have made several strategic investments in solid-state battery start-ups such as Sakti3 and Envia Systems

GM considered Envia a very strong prospect for providing the Bolt battery up until it flamed out, but aside from a $15M investment from Sir James Dyson earlier this year, less is known about Sakti3.

The automaker has produced 55 prototypes of the all-electric vehicle at plants in Seoul, South Korea, and Orion Township. They have been driven hard throughout GM's Milford Proving Grounds and early results are positive, engineers say.

The Bolt is expected to go on sale in early 2017 and will have a range between charges of more than 320 km (200 miles). General Motors plan to begin building its new Chevrolet Bolt electric car in October 2016.

BorgWarner to buy electric motor maker Remy for $950M

BorgWarner agreed to buy Remy for $951 million in cash, driving further consolidation of the auto-parts industry.

BorgWarner will pay $29.50 a share, a 44 percent premium from Remy’s closing price on Friday, according to a statement today. The price indicates an enterprise value of about $1.2 billion, BorgWarner said. The maker of turbochargers and transmission parts said the deal is set to close in the fourth quarter and should add to earnings in the first year because of purchasing efficiencies and other savings.

Demand for fuel-saving technology and global scale is pushing auto-parts makers to consolidate. In May, TRW Automotive Holdings Corp. was acquired by German auto supplier ZF Friedrichshafen AG for $12.4 billion.

“Our main focus has been organic growth, and that remains a prime path for us,” James Verrier, CEO of BorgWarner, said on a conference call. “But we’ve also been consistent about the need for M&A to add key technology to sustain that growth.”

The acquisition highlights the increasing importance of the electrification of the powertrain, which has not been a strength of BorgWarner’s, Verrier said.

BorgWarner rose 1 percent to $54.14 at 11:39 a.m. in New York, as Remy soared 42 percent to $29.18. This year through Friday, Remy had fallen 1.9 percent and BorgWarner had declined 2.4 percent.

Electric Powertrains

Buying Remy will add alternators, starters and hybrid motors, giving BorgWarner the ability to benefit as more powertrains blend electric power with traditional gasoline-fueled technology.

Some investors had been concerned that the move to hybrid engines would eventually cause BorgWarner to lose sales to automakers, Joseph Spak, an analyst with RBC Capital Markets, wrote in a research note today.

BorgWarner CFO Ron Hundzinski said he expects savings from the acquisition of at least $15 million annually within two years, in part by eliminating duplicate costs associated with a public company, and from lower purchasing expenses. He said he expects the Remy business to have profit margins in the mid-teens, similar to BorgWarner’s.

Former GM unit

Remy International, formerly known as Delco Remy, traces its roots to brothers Frank and Perry Remy, who developed magnetos, generators that used magnets to help start early automobiles. GM acquired Delco Remy in 1918 and spun it off in 1995. The name was changed to Remy International in 2004 and the Pendleton, Ind.-based company spent less than two months in bankruptcy in 2007.

Remy posted net income from continuing operations of $6.1 million last year on revenue of $1.2 billion. In 2013, it posted net income of $12.4 million on revenue of $1.1 billion.

Chevy Bolt testing confirms 320 km range target [VIDEO]

General Motors engineers say early testing of its upcoming Chevrolet Bolt EV is affirming their estimates that the car will have a range of 320 km (200 miles) between charges.

The automaker has produced 55 prototypes of the all-electric vehicle at plants in Seoul, South Korea, and Orion Township. They have been driven hard throughout GM's Milford Proving Grounds and early results are positive, engineers say.

"We have experienced 200 miles. We're pretty confident in that," said Pam Fletcher, GM executive chief engineer for electrified vehicles. "You can imagine we're going to eke out every mile of range we can."

Chevy unveiled the Bolt (that’s “Bolt” with a “B,” not to be confused with the existing plug-in hybrid Chevy Volt) concept at the Detroit Auto Show back in January, the hand-built prototypes have been testing since April. Vowing a 320 km (200-mile) range and a price tag of $30,000 after incentives, the Bolt is expected to enter production sometime in 2017.

Pam Fletcher, the chief executive engineer for electric vehicles at General Motors, also emphasized on Wednesday that GM’s electrification technology and manufacturing is U.S.-based. “Chevrolet’s electrification technology is very much grounded here in the U.S.,” Fletcher said in a video posted on GM’s site. She mentioned that the battery packs and electric drive units for the Volt are manufactured in Michigan and the electric motors are made in the U.S. “It’s a really a terrific story for technology and manufacturing and electrification in this country,” she said.

Chevrolet has committed to pricing the Bolt at about $30,000 after the $7,500 tax credit.

Hitachi Delivers High Output Prismatic Li-ion Battery Cell

Hitachi Automotive Systems today announced that the company will be supplying 5,000W/kg high output power density prismatic lithium-ion battery cells for the new model Chevrolet Malibu Hybrid to be sold by General Motors (GM) in 2016.

These prismatic lithium-ion battery cells being delivered for the 2016 new model Chevrolet Malibu Hybrid employ heat resistant separators to ensure the ionic conductivity between the positive and negative electrodes, achieving not only a high output power density of 5,000W/kg, but also a high level of safety. In addition to this, the battery's ability to maintain its high output power density in GM evaluations, even under extremely low temperatures such as the minus 30℃ cold region test, led to its adoption.

Hitachi's lithium-ion battery operations for vehicles began in 1999, leading the charge worldwide and beginning mass production of safe, high-performance, long lasting products. To date, a total of over 5 million lithium-ion batteries have been introduced into the market for commercial hybrid buses and trucks, as well as hybrid passenger cars.

The many years of supply performance for lithium-ion batteries as mass produced products, together with the accumulated production and quality management know-how garnered from feedback from the market, has led to an emphasis on high reliability and earned Hitachi a high reputation from car manufacturers both inside and outside of Japan.

In addition, last year Hitachi Automotive Systems integrated the lithium-ion battery manufacturer Hitachi Vehicle Energy's design and R&D departments, advancing lithium-ion batteries by using the electronic, control, and software technology the company possessed toward battery control system development.

Hitachi Automotive Systems will continue to contribute to the evolution of electrically driven vehicles through the strengthening of electric power train products, lithium-ion batteries, and more.

| Item | Specification |

|---|---|

| Size (mm) | 120×80×12 |

| Weight (kg) | 0.24 |

| Average Voltage (V) | 3.7 |

| Capacity (Ah) | 5.2 |

| Output Density (W/kg) | 5,000 |

| Energy Density (Wh/kg) | 80 |

Chevrolet-FNR autonomous EV concept

Chevrolet has created a vision of what it thinks a full autonomous all-electric vehicle of the future might look like.

Created by GM’s Pan Asia Technical Automotive Center the Chevrolet-FNR is an autonomous electric concept vehicle that boasts a futuristic capsule design. It has crystal laser headlights and taillights, dragonfly dual swing doors.

The Chevrolet-FNR features an extremely aero design focused on low drag powered by AWD magnetic hubless electric wheel motors along with autonomous wireless charging. A laundry list of imaginary specification like range and power output has been provided.

The Chevrolet-FNR is loaded with a range of sensors like roof-mounted radar that can map out the environment to enable driverless operation, Chevy Intelligent Assistant and iris recognition start. The Chevrolet-FNR can also serve as a “personal assistant” to map out the best route to the driver’s preferred destination.

In self-driving mode, the vehicle's front seats can swivel 180 degrees to face the rear seats, creating a more intimate setting. The driver can switch to manual mode through the gesture control feature.