For the first time, Audi is presenting a design and technical concept car at Pebble Beach Automotive Week in Monterey, California. The all-electric Audi PB18 e-tron presents a radical vision for the high-performance sports car of tomorrow. Broad and flat, visibly inspired by the wind tunnel and the race track, its very presence signals that it is destined to push boundaries. Its concept and exciting lines were created in the new Audi design studio in Malibu, California – where the brand’s design is consistently being updated for the future. The technical concept of the PB18 e-tron has benefitted from Audi's many years of winning the Le Mans racing series. The experts at Audi Sport GmbH, the high-performance subsidiary of Audi, were responsible for implementation. The abbreviated name “PB18 e-tron” refers both to the Pebble Beach venue for the premiere and to the technological DNA it shares with the successful LMP1 racing car Audi R18 e-tron.

Consistently focused concepts for use

At first sight, the Audi PB18 e-tron shows its kinship with another spectacular concept car from the brand – the Audi Aicon from 2017. This holds true not only for characteristic design elements like the side windows that angle inwards and the extremely extended wheel arches. The two concept cars from 2017 and 2018 also share their electric drive with solid-state battery as energy storage.

But their respective, consistently focused concepts for use make them polar opposites. While the Aicon was designed as a fully automated, long-distance luxury vehicle – a business jet for the road – the creators of the PB18 e-tron designed it as a radical driving machine for the racetrack and road. Dynamics and emotion top its list of specifications. Parameters like propulsive power, lateral acceleration and perfect ergonomics determine each detail. And driver-orientation is in a completely new dimension.

The internal working title at Audi for the showcar project was “Level Zero” – as an explicit way to differentiate it from the Levels 3, 4 and 5 of autonomous driving currently in focus at Audi. In the Audi PB18 e-tron, the driver is the one steering and stepping on the gas or brake pedal. There are therefore no complex systems for piloted driving on board and no comfort features to add weight. In their place are a driver’s seat and cockpit that are integrated into an inner monocoque shell that can be slid laterally. When driven solo, the monocoque can be positioned in the center of the interior as in a monoposto – the perfect location for the racetrack. This is made possible not least by the by-wire design of the steering and pedals; a mechanical connection of the control elements is not needed.

Gael Buzyn is Head of the Audi Design Loft in Malibu – where the Audi PB18 e-tron was born. He describes the most important item in the specifications: “We want to offer the driver an experience that is otherwise available only in a racing car like the Audi R18. That’s why we developed the interior around the ideal driver’s position in the center. Nevertheless, our aim was to also give the PB18 e-tron a high degree of everyday usability, not just for the driver, but also for a potential passenger.”

When the driver’s monocoque is slid into the side position, from where the PB18 e-tron can be steered in everyday driving like a conventional road vehicle, there is room for a passenger. An additional seat can be accessed on the other side, integrated low above the ground and equipped with a three-point seatbelt. The driver also benefits when getting in and out from the easily accessible outside position of the monocoque, which can be moved when the door is open up to the sill.

Inspiration drawn from motorsport

The Audi PB18 e-tron package follows the traditional architecture of a mid-engine sports car with a cab that is positioned far forward. The car’s center of gravity is located behind the seats and in front of the rear axle – which benefits the driving dynamics. This does not involve the engine-transmission unit, as in a car with a conventional drive system, but rather the battery pack.

A mix of aluminum, carbon and multi-material composites ensures the body of the Audi PB18 e-tron has a low basic weight. Not least thanks to the innovative and comparatively light solid-state battery, a total weight of less than 1,550 kg (3,417.2 lb) can be expected.

The PB18 e-tron is 4.53 meters long, 2 meters wide and just 1.15 meters tall (14.5 x 6.4 x 4.6 ft). These dimensions alone speak of a classical sports car. The wheelbase is 2.70 meters (8.9 ft) and the overhangs are compact. Viewed from the side, the eye is drawn to the gently sloping roof line which is pulled far to the back and features massive C-pillars. Together with the large and almost vertical rear window, this design is reminiscent of a shooting brake concept – the synthesis of a coupé with the rear of a station wagon. The result is not only a distinctive silhouette but also, with 470 liters (16.6 cubic ft), a clear bonus in terms of cargo space – usually a deficit in sports cars. An exclusive luggage set customized to fit the cargo space helps to make optimum use of the luggage compartment – even if the luggage in this car frequently consists of nothing but a helmet and racing overall.

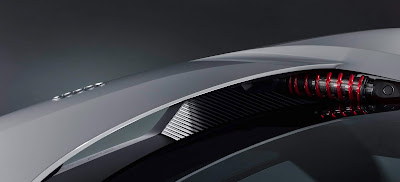

A flat red band of lights extends across the entire width of the rear and underscores the horizontal orientation of the vehicle body. The cabin, placed on the broad shoulders of the wheel arches, appears almost dainty from the rear. The rear diffuser air outlet has been raised high – another functional feature borrowed from motorsport. The diffuser can be moved downward mechanically to increase downforce. The rear spoiler, which normally is fixed, can be extended rearward for the same purpose.

The widely extended wheel arches located opposite the central cabin are noticeable from every angle. They emphasize the extremely wide track of the PB18 e-tron and thereby illustrate the lateral dynamic potential of the car and the obligatory quattro drive. The large 22-inch wheels, each with eight asymmetrically designed spokes are reminiscent of turbine inlets – together with the air inlets and outlets of the wheel arches, their rotation ensures excellent air supply to the large carbon brake discs.

The front is dominated by the familiar hexagon shape of the Singleframe grille, with an emphatically wide and horizontal cut. The brand logo is placed above at the front of the hood, in the typical Audi sports car style. Large air inlets to the left and right of the Singleframe supply the necessary cooling air to the brakes and the front electric motor. Wide and flat light units with integrated digital matrix technology and laser high-beam headlights complete the face of the PB18 e-tron.

The laser high-beam headlight with its enormous range is especially emblematic of the transfer of know-how from motorsport: This technology made its debut in the Le Mans R18 racing car, where the maximum light output at speeds above 300 km/h offered a crucial safety advantage at night as well.

The Audi designers have taken a new tack for air flow through the front hood. The hood dips deeply and acts as a lateral bridge running across the nose, connecting the two emphatically accentuated fenders and also doubling as an air deflector. A design that is thoroughly familiar from racing prototypes.

At the same time, this layout offers the driver a unique quality of visibility, and not just on the race track. Looking through the large windshield from the low seating position, the driver sees precisely into the opening of the ventilated hood and onto the road, and can thus perfectly target the course and apex of the curve. Mounted within the field of vision is a transparent OLED surface. The ideal line of the next curve can be shown on it, for example, precisely controlled with data from navigation and vehicle electronics. In normal road traffic, on the other hand, the direction arrows and other symbols from the navigation system find a perfect place here in the driver’s field of vision, analogous to a head-up display.

The large-format cockpit itself is designed as a freely programmable unit and can be switched between various layouts for the racetrack or the road, depending on the scenario for use.

Three electric motors and quattro drive

The concept uses three powerful electric motors – one up front and two in the rear. The latter are centrally located between the steering knuckles, each directly driving one wheel via half-shafts. They deliver power output of up to 150 kW to the front axle and 350 kW to the rear – the Audi PB18 e-tron is a true quattro, of course. Maximum output is 500 kW, with boosting, the driver can temporarily mobilize up to 570 kW. The combined torque of up to 830 newton meters (612.2 lb-ft) allows acceleration from 0 to 100 km/h (62.1 mph) in scarcely more than 2 seconds – a speed that differs only marginally from that of a current LMP1 prototype.

In normal road traffic, the driver can limit the maximum speed in favor of range. This limitation is easy to deactivate on the racetrack and can be adapted to local conditions.

The focus is on not just powerful performance but also maximum efficiency. While being driven, the Audi PB18 e-tron recovers large amounts of energy: up to moderate braking, the electric motors are solely responsible for decelerating the vehicle. The hydraulic brakes only come into play for heavy braking.

The concept of separate electric motors on the rear axle offers major advantages when it comes to sporty handling. The Torque Control Manager, which works together with the Electronic Stabilization Control (ESC), actively distributes the power to the wheels of the front and rear axles as needed. This torque control provides for maximum dynamics and stability. Thanks to the virtually instantaneous response of the electric motors, the control actions are lightning-quick. The drive concept of the Audi PB18 e-tron adapts perfectly to every situation, whether involving transverse or longitudinal dynamics.

The liquid-cooled solid-state battery has an energy capacity of 95 kWh. A full charge provides for a range of over 500 kilometers (310.7 miles) in the WLTP cycle. The Audi PB18 e-tron is already designed for charging with a voltage of 800 volts. This means the battery can be fully recharged in about 15 minutes.

The Audi PB18 e-tron can also be charged cordlessly via induction with Audi Wireless Charging (AWC). This is done by placing a charging pad with integral coil on the floor where the car is to be parked, and connecting it to the power supply. The alternating magnetic field induces an alternating voltage in the secondary coil fitted in the floor of the car, across the air gap.

High-tech from the LMP1 sport: the suspension

The front and rear have independent suspension on lower and upper transverse control arms, and, as commonly found in motor racing, a push-rod system on the front axle and pull-rod system on the rear – in both cases with adaptive magnetic ride shock absorbers. The suspension of the Audi R18 e-tron quattro Le Mans racing car served as the model for the basic architecture.

The wheels measure 22 inches in diameter and are fitted with 275/35 tires in the front and 315/30 in the back. Large carbon brake discs with a 19-inch diameter, in conjunction with the electric brake, safely and steadily decelerate the Audi PB18 e-tron even in tough racetrack conditions.

The path to volume production – electric mobility at Audi

Audi has been developing vehicles with all-electric or hybrid drive since back in the late 1980s. The first production offering of a car combining a combustion engine with an electric motor was the Audi duo from 1997, which occupied the body of an A4 Avant. A landmark technological development for electric cars was the R8 e-tron, which was unveiled at the 2009 Frankfurt Motor Show and in 2012 set a record lap time for an electric car on the North Loop of the Nürburgring.

Audi added a first plug-in hybrid to its range in 2014 in the guise of the 150 kW (204 hp) A3 e-tron – its battery units can be recharged by recuperation and cable, and give it an all-electric range of up to 50 kilometers in the NEDC. The Q7 e-tron made its debut in 2016: It is powered by a 3.0 TDI engine combined with an electric motor, with a combined 275 kW (373 hp) and 700 Nm (516.3 lb-ft) of torque. It accelerates from a standing start to 100 km/h (62.1 mph) in 6.2 seconds and is particularly efficient. In all-electric mode, it has a range of up to 56 kilometers (34.8 miles) while producing zero local emissions. It is also the world’s first plug-in hybrid with a V6 compression ignition engine and quattro drive.

Another concept car unveiled by Audi in 2015 at the Frankfurt Motor Show, was the e-tron quattro concept – the forerunner of the brand’s first all-electric-drive production automobile. As a radically reconfigured SUV it offers a range of more than 400 kilometers (248.5 miles) in the WLTP cycle with the spaciousness and comfort of a typical full-size automobile from Audi. The production version of this groundbreaking e-SUV, named Audi e-tron, will debut in September 2018.

Roadtrip, circuit or piloted city-mobile – a new mobility service

Audi has meanwhile been building a new family of visionary automobiles since 2017 as a preview for the next decade – electrically powered and precisely focused on their respective use scenarios. Cars currently in the market are always conceived as a versatile synthesis between highly conflicting requirement profiles – in practice, this often means compromises must be made. In contrast, the current concept cars will occupy a new, consistent position in an increasingly diversified market. The Audi Aicon long-distance luxury vehicle started things off at the IAA 2017; the PB18 e-tron is now marking another milestone. Additional vehicle concepts, such as those for example for urban traffic, are already being developed and will make their public debut in the coming months.

As part of a premium sharing pool with highly individual models, they will all sharpen the profile of the Audi brand even further in the future – as custom-tailored products and services for highly demanding customers who want to combine mobility, emotion and experience in every situation of their lives. These customers can then decide whether they only want to use the vehicle of their choice temporarily and exchange it for another when needed, or if they would rather purchase it permanently, as today.